Place of Origin: Shenzhen, Guangdong, China

Brand Name: Hithunder

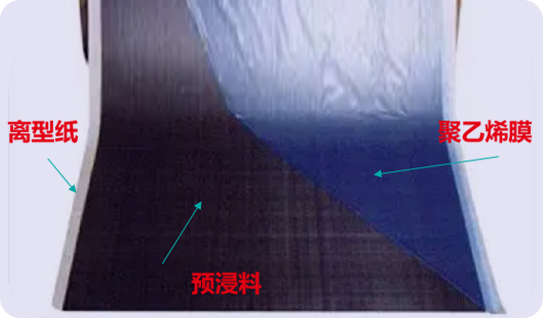

Material: 100% Carbon Fiber

Carbon content: 90%

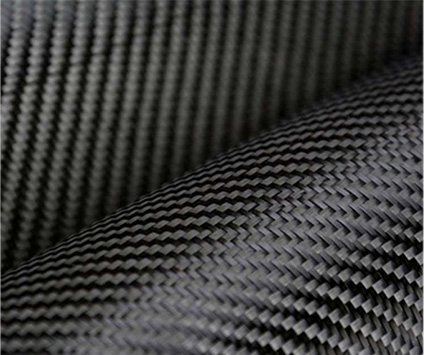

Color: Black

Fiber type: 3K (available: 6K, 12K, 25K, 35K, 50K)

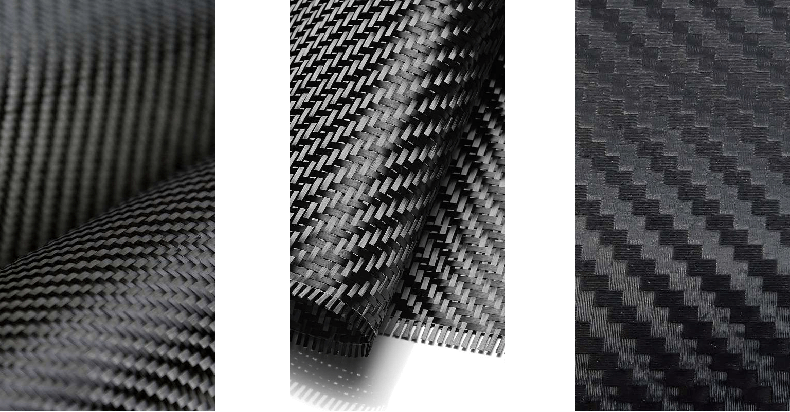

Pattern: Twill, plain, jacquard weaver

Thickness: 0.23~0.34mm

Weight: 100-640gsm

Width: 1000mm (custom width on demand)

Package: Pp bag in Carton

Total Length: 100meters/roll

Standard: ASTM

Definition

Definition