Welcome to the official website

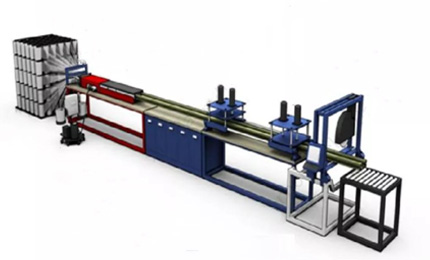

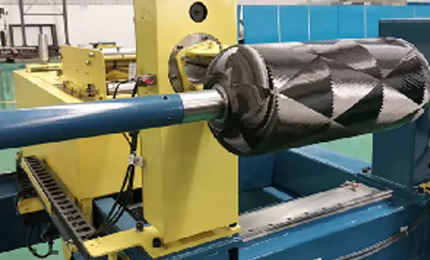

Advanced process technology

Advanced process technology

Privacy Statement

Data update in progress......

+86-0755 2992 9560

hsdksz@hithunder.cn

Room 908, 9th Floor, Yingshuo Business Building, No. 8, Yizhan 4th Road, Shapu Community, Songgang Street, Bao'an District, Shenzhen, Guangdong