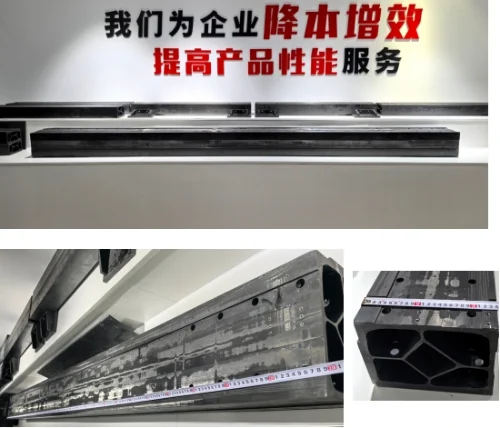

Place of Origin: Guangdong, China

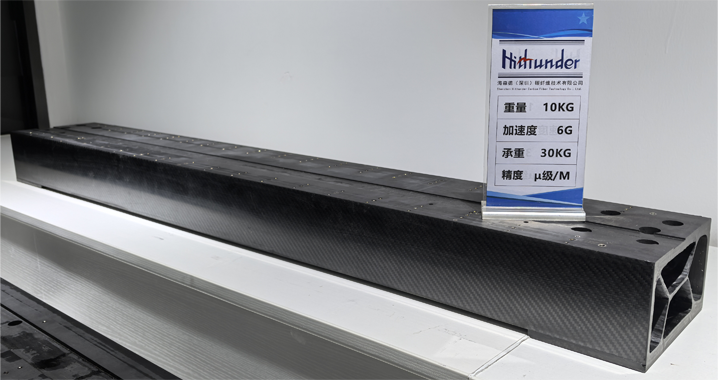

Brand Name: Hithunder

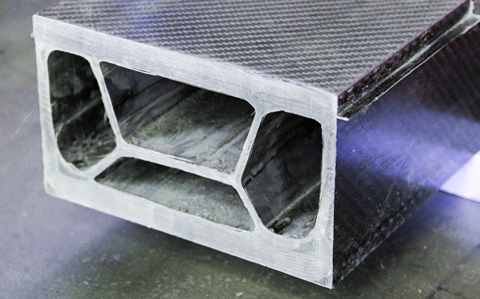

Material: 100% Carbon Fiber

Color: Black

Fiber type: 3K

Pattern: Twill

Wall hickness: 9mm

Weight: 10KG

Dimensions: 173(W) X 95(H) X 1200(L) mm (custom dimensions on demand)

Place of Origin: Guangdong, China

Brand Name: Hithunder

Material: 100% Carbon Fiber

Color: Black

Fiber type: 3K

Pattern: Twill

Wall hickness: 9mm

Weight: 10KG

Dimensions: 173(W) X 95(H) X 1200(L) mm (custom dimensions on demand)

Carbon fiber beams, also known as Rectangular Multi-cell Carbon Fiber Tube, Hollow Multichamber Carbon Fiber Tubes, or Anti-torsional non-standard Carbon Fiber Tubes, are a revolutionary advancement in the construction of CNC machine tools, offering superior performance compared to traditional steel and aluminum beams. In the world of modern industry, CNC machines are indispensable, with their gantry configuration being a key structural element that supports the beam—the fundamental moving component. The efficiency, precision, and stability of this beam is paramount, as it directly affects the machine's operational capabilities.

While steel beams are known for their stability and precision, their substantial weight can be a liability in applications requiring high-speed operation. To overcome this, machines would need to be paired with high-power motors and torque capabilities, which can be both costly and reach a point of diminishing returns. Aluminum alloy beams, though lighter, still fall short in terms of speed and acceleration, and their susceptibility to deformation and temperature-induced accuracy shifts require frequent recalibration.

CFBs address these challenges by combining high rigidity, toughness, and remarkably low weight. With a density of 1.6 and a modulus of elasticity exceeding 230 GPa, carbon fiber rivals the strength of steel while significantly reducing weight. This makes CFBs an ideal material for machine tool components that demand rigidity and dimensional stability without the drawbacks of traditional metals.

Performance and Precision

The low weight of CFBs allows for increased acceleration and speed, enhancing machining efficiency and the precision of complex curved surface operations. Unlike aluminum alloys, carbon fiber's inherent properties ensure consistent performance across varying temperatures, eliminating the need for periodic recalibration.

Elasticity and Durability

Carbon fiber, composed primarily of carbon, is an inorganic and brittle material with a certain degree of elastic deformation capacity. It maintains structural integrity with a low breaking elongation of around 2%, indicating its resilience and ability to return to its original shape after stress is removed.

1. Improving Product Performance at Lower Costs: CFBs enable higher machine tool acceleration (up to 6G) compared to traditional metal beams, without requiring costly upgrades to other components. The lightweight nature of CFBs reduces force requirements on motors and other parts, allowing the use of less powerful (and less expensive) drives and reducers.

2. Extending Machine Tool Lifespan and Reducing After-Sales Costs: CFBs' lower weight leads to reduced wear on guide rails and racks, extending the service life of critical components. The rigidity and no creep in CFBs eliminate the need for frequent beam adjustments, reduce labor and maintenance costs. CFBs' elastic deformation properties help reduce the risk of unplanned shutdowns due to external impacts or control system failures.

3. Energy Savings: The lightweight CFBs reduce the energy consumption of drive motors by around 20%, lowering the energy cost per unit of production.

| Model | Cross-section | Material | Wall Thickness | Beam Length | Weight | Loads | Deformation Amount@Acceleration | ||

|---|---|---|---|---|---|---|---|---|---|

| Shape | Size(mm) | ||||||||

| CFB-R17395 | Rectangle | 173X95 | T300 | 5mm | 1200mm | 9.62KG | 20KG | 0.0239mm @1g | 0.0255mm @4g |

| 0.0243mm @2g | 0.0275mm @6g | ||||||||

| Rectangle | 173X95 | T300 | 10mm | 1200mm | 13.78KG | 20KG | 0.0066mm @1g | 0.0086mm @4g | |

| 0.0070mm @2g | 0.0109mm @6g | ||||||||

| Rectangle | 173X95 | T300 | 15mm | 1200mm | 17.57KG | 20KG | 0.0043mm @1g | 0.0063mm @4g | |

| 0.0047mm @2g | 0.0082mm @6g | ||||||||

| Rectangle | 173X95 | T300 | 20mm | 1200mm | 20.97KG | 20KG | 0.0035mm @1g | 0.0053mm @4g | |

| 0.0040mm @2g | 0.0068mm @6g | ||||||||

| CFB-R200120 | Rectangle | 200X120 | T300 | 5mm | 1800mm | 17.50KG | 20KG | 0.0347mm @1g | 0.0380mm @4g |

| 0.0354mm @2g | 0.0420mm @6g | ||||||||

| Rectangle | 200X120 | T300 | 10mm | 1800mm | 25.24KG | 20KG | 0.0131mm @1g | 0.0166mm @4g | |

| 0.0139mm @2g | 0.0204mm @6g | ||||||||

| Rectangle | 200X120 | T300 | 15mm | 1800mm | 32.40KG | 20KG | 0.0094mm @1g | 0.0125mm @4g | |

| 0.0100mm @2g | 0.0157mm @6g | ||||||||

| Rectangle | 200X120 | T300 | 20mm | 1800mm | 38.99KG | 20KG | 0.0080mm @1g | 0.0107mm @4g | |

| 0.0087mm @2g | 0.0132mm @6g | ||||||||

| CFB-R241185 | Rectangle | 241.5X185 | T300 | 5mm | 2800mm | 26.66KG | 50KG | 0.0654mm @1g | 0.1224mm @4g |

| 0.0816mm @2g | 0.1673mm @6g | ||||||||

| Rectangle | 241.5X185 | T300 | 10mm | 2800mm | 52.30KG | 50KG | 0.0283mm @1g | 0.0468mm @4g | |

| 0.0332mm @2g | 0.0629mm @6g | ||||||||

| Rectangle | 241.5X185 | T300 | 15mm | 2800mm | 75.92KG | 50KG | 0.0208mm @1g | 0.0321mm @4g | |

| 0.0237mm @2g | 0.0422mm @6g | ||||||||

| Rectangle | 241.5X185 | T300 | 20mm | 2800mm | 97.52KG | 50KG | 0.0175mm @1g | 0.0257mm @4g | |

| 0.0195mm @2g | 0.0333mm @6g | ||||||||

| The actual SPEC may vary depending on your specific needs! | |||||||||

1 . With its own independent intellectual property rights, the multi-chamber structural design of the load-bearing beam is meticulously ground to achieve a straightness of 0.01mm for every 1000mm.

2. The designed load-bearing and deformation capacity can meet the precision requirements for machine tool motion even under high acceleration conditions.

3. The customizable cross-sectional dimensions and structural design ensure the stability of the entire framework when under load. And it's all one-molding, without secondary processing.

4. The current longest beam size available is 4.5 meters, but we can develop it further to meet customer needs, with the capability to extend up to 7.5 meters or longer.

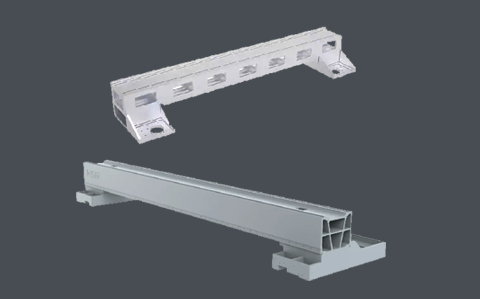

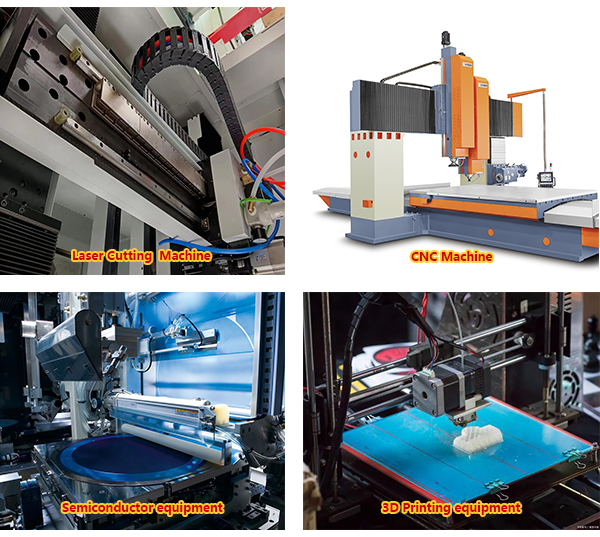

1. CNC machine tools

2. Laser cutting machines

3. 3D printing equipment

4. Other gantry or overhead structure equipment

| Model | Cross-section Size(mm) | Material | Wall Thickness | Length(mm) | Weight | Load | Flatness (μm/m) | Deformation Amount @Acceleration |

|---|---|---|---|---|---|---|---|---|

| CFB-R17395-A | 173X95 | T300 | 9mm | 1240 | 10KG | 30KG | 6 | 0.0159mm @6g |

| CFB-R17395-B | 173X95 | T300 | 9mm | 1240 | 15KG | 30KG | 6 | 0.0135mm @6g |

| Model | Cross-section Size(mm) | Material | Wall Thickness | Length(mm) | Weight | Load | Flatness (μm/m) | Deformation Amount @Acceleration |

|---|---|---|---|---|---|---|---|---|

| CFB-R241185 | 241.5X185 | T300 | 11mm | 3290 | 60KG | 75KG | 6 | 0.0422mm @2g |

| Material | Density (g/cm3) | Tensile Strength (MPa) | Specific Strength (Mpa.(g/cm3)-1) | Tensile Modulus (GPa) | Specific Modulus (GPa.(g/cm3)-1) |

|---|---|---|---|---|---|

| Carbon Steel (Q345) | 7.8 | 480 | 63 | 206 | 26 |

| Stainless Steel (S301) | 7.9 | 820 | 105 | 195 | 25 |

| Aluminum Alloy | 2.8 | 420 | 151 | 72 | 25.9 |

| Carbon Fiber Composites | 1.6 | 1760 | 1100 | 130 | 81 |

| Fiberglass Composites | 2 | 1245 | 623 | 48 | 24.1 |

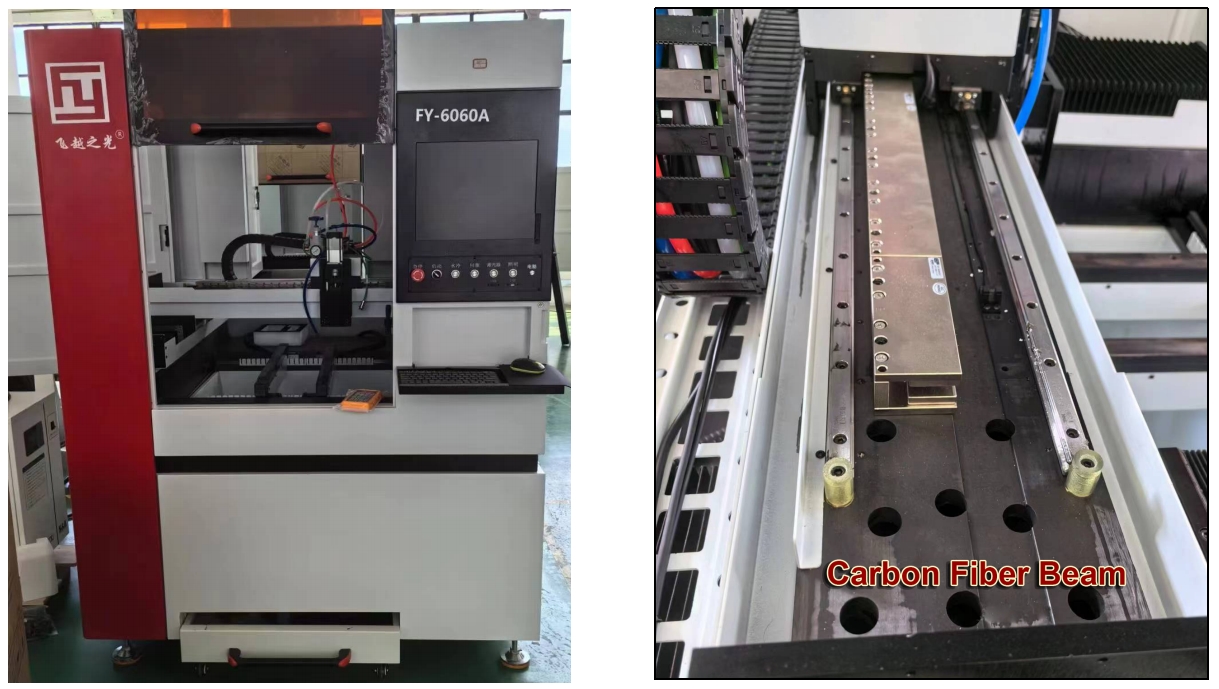

FEIYUE:

FEIYUE:

Feiyue Laser Equipment Co. Ltd, a renowned manufacturer of precision cutting machine tools, has achieved a remarkable breakthrough through the adoption of carbon fiber beams. This upgrade has directly boosted the machine's acceleration from 1g to 2g, while ensuring long-term machining accuracy at the micro (μm) level. Additionally, the performance of the machines has become more stable. This transformative innovation not only guarantees the precision and reliability of Feiyue Laser's cutting machine tools but also sets them apart from competitors. The company has successfully forged collaborations with militaryindustrial enterprises, resulting in heightened economic benefits.

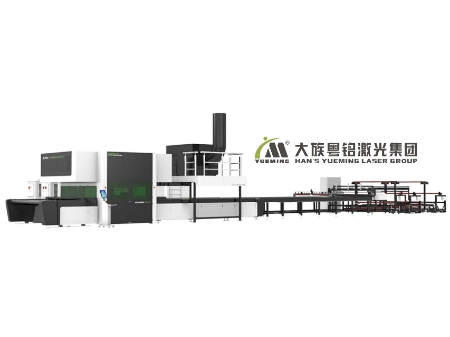

YUEMING LASER :

YUEMING LASER :

YUEMING LASER GROUP, a pioneering enterprise, has achieved a remarkable breakthrough by replacing the original metal beams on their machine tools with carbon fiber beams. This simple replacement propelled the machines' acceleration from 1g to an astounding 6g, all without the need to replace any other components. Moreover, the machines can maintain stable operation at 4g for extended durations. This technological advancement brings about a significant enhancement in performance and added value for their specialized laser cutting machines for airbag production. Not only does it elevate productivity, but it also leads to substantial gains in product profitability.

Privacy Statement

Data update in progress......

+86-0755 2992 9560

hsdksz@hithunder.cn

Room 908, 9th Floor, Yingshuo Business Building, No. 8, Yizhan 4th Road, Shapu Community, Songgang Street, Bao'an District, Shenzhen, Guangdong