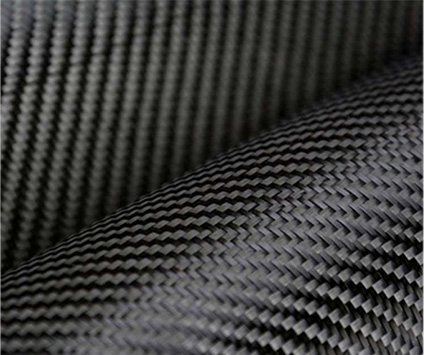

As a high-precision mechanical structural component, carbon fiber beams can effectively help companies reduce costs, increase efficiency, and improve product performance.

1. Improve product performance at lower costs

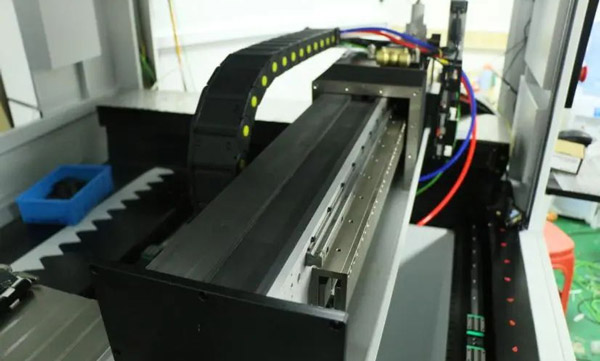

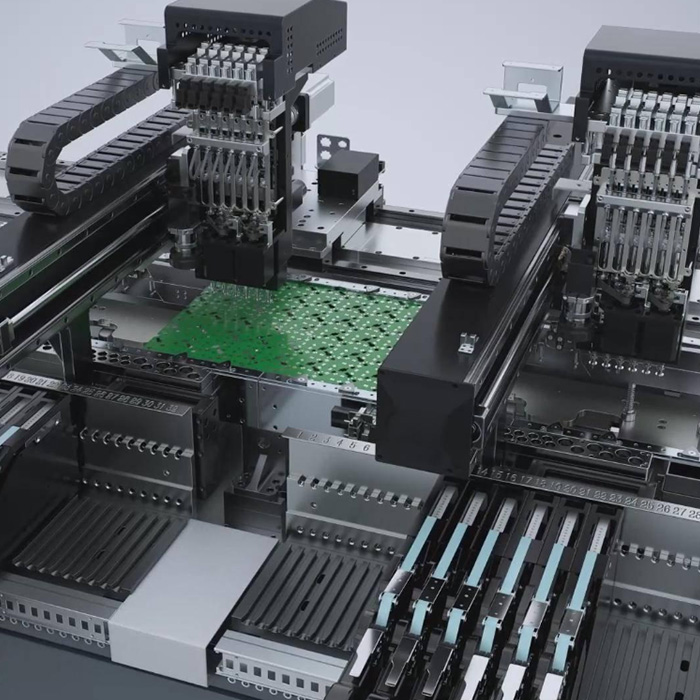

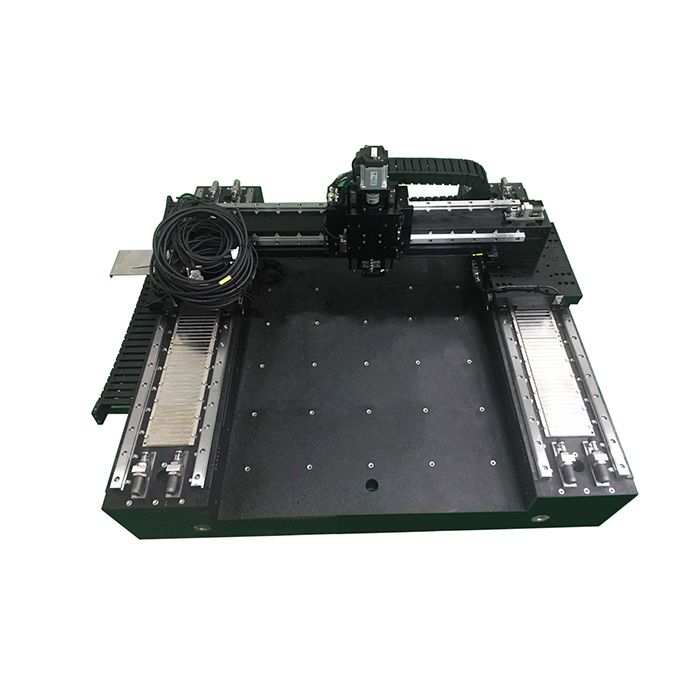

A top company in the laser industry in Dongguan uses carbon fiber beams to replace the original metal beams. Without any changes in all accessories (only the beams are replaced), the machine tool acceleration is directly increased from 1G to 6G and can maintain stable operation at 4G for a long time. If metal beams are used to increase acceleration, the cost will be much greater than that of carbon fiber beams.

At present, the dynamic acceleration of most machine tools is maintained at the level of 1G. If the goal is to increase the acceleration to 2G, metal beam machine tools require more powerful drives and reducers to ensure rapid acceleration and precise positioning of the beam. In addition, as the acceleration of the beam increases, the bed will be more likely to shake, which requires the bed to be increased in weight to maintain stability. At the same time, the rack must also be recommended to cope with long-term stable operation under larger loads.

In contrast, the use of carbon fiber beams shows obvious cost advantages. It does not require increasing the overall weight of the machine tool or upgrading the rack, and can even reduce the performance requirements for motors such as drives and reducers. Due to the lightweight nature of carbon fiber beams, the driving force required is much lower than that of metal beams, which means that even with ordinary motors and racks, accelerations of 2g or even higher can be easily achieved within the load range, avoiding the need for overloading. Frequent failures caused by heavy workload.

If the acceleration is to be increased to 3G or 4G, the cost gap between metal beams and carbon fiber beams will be even greater, and the performance achieved by using metal beams is no longer economical and practical (the current international high index is 2.5g). Carbon fiber beams can easily break through the performance upper limit of metal beams, achieve more efficient acceleration improvements, and show obvious cost reduction effects.

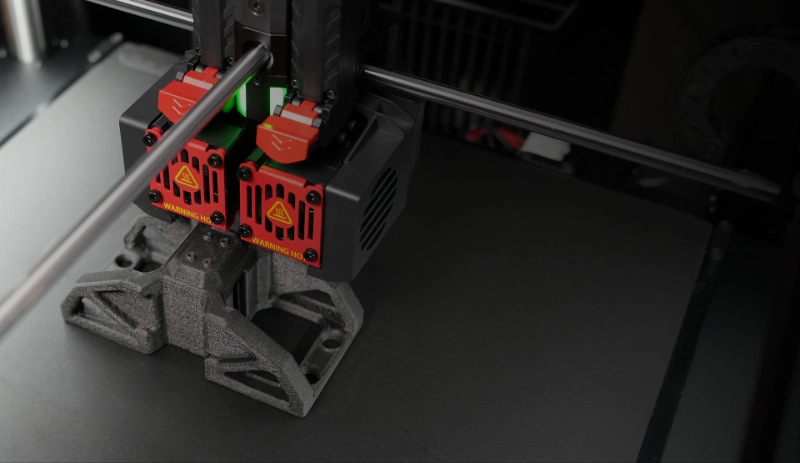

2. Easily increase acceleration and comprehensive processing speed

Relying on the transcendent characteristics of carbon fiber materials, carbon fiber beams can greatly improve the motion performance of machine tools. With the same configuration, the machine tool acceleration can be easily increased to 48, and the overall processing speed can be increased by 50-60%, achieving a significant jump in production efficiency.

3. Higher accuracy and can be maintained for a long time

Compared with traditional CNC-processed steel beams and aluminum beams, carbon fiber beams processed by high-precision grinders show more obvious advantages in precision control. Their accuracy per meter can reach U level, and because of their extremely high strength The physical properties enable long-term stability and high precision, providing users with more reliable and precise processing solutions.

4. Extend the service life of machine tools and reduce parts replacement costs

Since the carbon fiber beam is lighter, it means that the guide rails and racks that bear the main motion loads will wear less, which can greatly increase the service life of the guide rails and racks, further extending the service life of the equipment, and also reducing the need for users to replace related accessories. the cost of;

5. Reduce energy consumption per unit product

Because the carbon fiber beam is lighter, the load on the drive motor is reduced and energy consumption is reduced by about 20%. The same energy consumption is used in more parts, which is equivalent to reducing the energy consumption per unit product.

6. Significantly reduce after-sales costs

Since the rigidity of carbon fiber beams is close to that of steel beams, much higher than that of aluminum beams, and the material has no creep characteristics, there will be no loss of accuracy due to deformation during long-term use, and the need for maintenance every 3-6 months can be eliminated. Cross beam adjustment work saves a lot of after-sales manpower and time costs;

In addition, the carbon fiber beam has the ability to elastically deform. When the machine tool encounters force majeure elements such as control system failure or external impact, as long as the acid fiber beam is not damaged internally, once the external force is removed, it can quickly rebound to its original state without any problems. Produce long-term deformation.

It can be said that carbon fiber beams require almost no additional after-sales service after factory installation, and it also helps reduce the need for after-sales maintenance of other parts of the machine tool. For equipment manufacturers, this can significantly reduce after-sales costs and improve product competitiveness; for users, it can also effectively reduce downtime caused by equipment maintenance, improve production efficiency, and reduce energy consumption.

In today's increasingly fierce market competition, product homogeneity is serious, and machine tools using carbon fiber beams will undoubtedly become the best in the market. Its excellent dynamic performance and transcendent control accuracy will bring users obvious advantages in production efficiency, capacity and competitiveness of high value-added orders, helping enterprises to stand out in the fierce market competition and achieve higher economic benefits.

In the future, we will continue to increase the research and development and innovation of carbon fiber beams and continuously improve the performance and quality of our products. At the same time, we will actively expand the market, strengthen cooperation with partners, and promote the application of carbon fiber beams in various fields. We firmly believe that carbon fiber beams will become an important development direction in the future material field and make greater contributions to the sustainable development of society.

The above is about the product application range, relative advantages and future development of carbon fiber beams. If you have more questions or cooperation intentions, please feel free to contact us. Thanks!