Carbon fiber has become a critical material in industries ranging from aerospace and automotive to sports equipment and renewable energy. Its high strength-to-weight ratio, durability, and resistance to extreme conditions make it a preferred choice for manufacturers looking to enhance performance and efficiency. However, selecting the right carbon fiber production company is crucial to ensuring quality, reliability, and long-term success.

At Hithunder Composite Materials Technology, we specialize in high-performance composite materials, integrating advanced aerospace and military-grade carbon fiber technologies into civilian and commercial applications. Our expertise ensures that businesses receive top-tier carbon fiber solutions tailored to their specific needs.

This article will guide you through the key factors to consider when choosing a carbon fiber production company to ensure you make an informed decision.

1. Understanding Your Business Needs

Before selecting a carbon fiber manufacturer, it's essential to evaluate your specific requirements:

✔ Application – Will the carbon fiber be used in automotive, aerospace, sports equipment, construction, or another industry?

✔ Performance Requirements – Do you need high-strength, high-temperature resistance, or lightweight properties?

✔ Production Scale – Are you looking for customized solutions or mass production?

✔ Budget Constraints – Does the supplier offer cost-effective solutions without compromising quality?

Understanding these factors will help you find a production company that aligns with your business objectives.

2. Evaluating the Manufacturer’s Expertise and Experience

Choosing a company with proven expertise and experience in carbon fiber production ensures high-quality materials and reliable performance.

Key Factors to Consider:

✔ Years in the Industry – Look for companies with a strong track record in carbon fiber manufacturing and innovation.

✔ Technology & R&D Capabilities – Does the company invest in advanced manufacturing techniques and material science research?

✔ Industry Certifications – Ensure compliance with ISO9001, aerospace, automotive, and other industry standards.

Why Choose Hithunder Composite Materials Technology?

At Hithunder, we bring years of expertise in composite material research and production, continuously integrating cutting-edge aerospace technologies into civilian and industrial applications. Our advanced R&D capabilities ensure that our carbon fiber products meet the highest industry standards.

3. Assessing Production Capabilities and Quality Control

A top-tier carbon fiber production company should have state-of-the-art manufacturing facilities and strict quality control processes to ensure consistent product performance.

Key Production Capabilities to Look For:

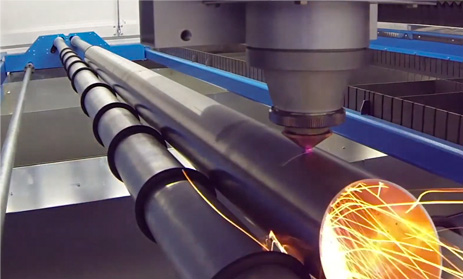

✔ Autoclave Curing & Prepreg Processing – Ensures high-quality carbon fiber composites.

✔ Resin Transfer Molding (RTM) & Compression Molding – Provides strong, durable components.

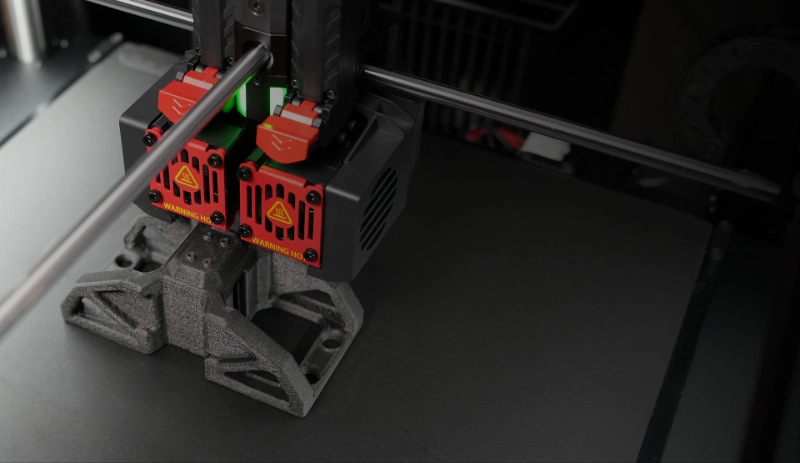

✔ Custom Engineering & Prototyping – Offers tailored solutions for unique applications.

✔ Automated Weaving & Layering – Guarantees precision and uniformity.

Hithunder’s Commitment to Quality

At Hithunder Composite Materials Technology, we implement stringent quality control measures in every step of production, ensuring our carbon fiber products meet aerospace-grade performance. Our manufacturing processes include advanced autoclave curing, high-precision molding, and automated fiber placement, making our solutions ideal for high-performance applications.

4. Customization and Innovation Capabilities

Every industry has unique requirements, and a one-size-fits-all approach doesn’t work for high-performance carbon fiber applications.

Key Customization Factors:

✔ Tailored Fiber Weaves & Resins – Different industries require different composite properties.

✔ Precision Engineering for Specific Components – From automotive chassis to drone frames, manufacturers should provide custom designs.

✔ Advanced Surface Treatments & Coatings – To enhance durability, conductivity, or heat resistance.

How Hithunder Leads in Innovation

We integrate aerospace and military-grade composite technologies into industrial and civilian applications, ensuring superior strength, precision, and performance. Our R&D team works closely with clients to develop custom carbon fiber solutions that meet industry-specific demands.

5. Sustainability and Environmental Responsibility

As industries move towards eco-friendly materials and sustainable production, it is essential to select a company that prioritizes environmental responsibility.

Eco-Friendly Carbon Fiber Practices:

✔ Energy-Efficient Manufacturing – Reduces carbon footprint and material waste.

✔ Recyclable Carbon Fiber Composites – Innovations in carbon fiber recycling technology.

✔ Low-Emission Production Processes – Compliance with global environmental regulations.

At Hithunder, we adopt sustainable production techniques, ensuring that our carbon fiber materials contribute to a greener future while maintaining top-tier performance.

6. Supply Chain and Delivery Efficiency

A reliable carbon fiber production company should provide on-time delivery and consistent supply chain management to support your business operations.

Key Supply Chain Considerations:

✔ Global Distribution Network – Ensures timely delivery and reduced logistics costs.

✔ Inventory Management – Prevents production delays and shortages.

✔ Strong Partnerships – Collaborates with trusted suppliers for raw materials.

With Hithunder’s efficient supply chain and global distribution capabilities, we ensure that our clients receive high-quality carbon fiber materials with minimal lead time.

7. Cost vs. Value: Finding the Right Balance

While cost is a crucial factor, choosing the cheapest option can lead to quality issues, performance failures, and long-term losses. Instead, focus on value for money, considering factors like:

✔ Material Quality & Durability – High-quality carbon fiber lasts longer and performs better.

✔ Precision Engineering & Customization – Tailored solutions maximize efficiency.

✔ Long-Term Cost Savings – Superior materials reduce maintenance and replacement costs.

Hithunder’s Competitive Pricing & Premium Quality

We provide cost-effective carbon fiber solutions without compromising on performance or reliability, ensuring maximum return on investment for our clients.

Conclusion

Choosing the right carbon fiber production company is a critical decision that impacts product quality, performance, and business success. By considering expertise, production capabilities, innovation, sustainability, and supply chain efficiency, you can make an informed choice.

At Hithunder Composite Materials Technology, we leverage aerospace-grade composite expertise to deliver high-performance carbon fiber solutions tailored to diverse industries. Our commitment to quality, innovation, and sustainability makes us a trusted partner for businesses worldwide.