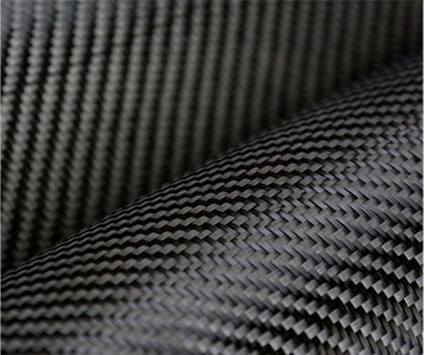

As the demand for 3D printing grows across industries, achieving precision, efficiency, and reliability has become paramount. Among the components that significantly enhance the performance of 3D printers, Carbon Fiber Circular Rails solutions have emerged as game-changers. Hithunder's Carbon Fiber Circular Rails combine cutting-edge materials with advanced engineering, offering unparalleled advantages in stability, accuracy, and energy efficiency. This innovation is paving the way for a smoother, more productive 3D printing experience.

Why Choose Carbon Fiber Circular Rails?

Carbon fiber circular rails are designed to address some of the most common challenges faced by 3D printing systems: vibration, deflection, and inefficiency. Compared to traditional metal rails, carbon fiber is both lighter and stronger, which results in significant performance improvements:

Reduced Vibration and Deflection Errors

The low weight of carbon fiber rails minimizes vibrations during operation. This reduction in vibration leads to enhanced printing stability and greater precision, which is critical for producing high-quality prints consistently.High Load Capacity with Lightweight Design

Despite being incredibly lightweight, these rails are engineered to handle high load capacities, especially on the Z-axis. This feature ensures reliable performance even during intensive printing tasks.Energy Efficiency

Lighter rails mean less energy is required to move the 3D printer’s parts. This leads to energy savings of 30% to 60%, reducing operational costs and contributing to a more sustainable printing process.

Key Features of Hithunder’s Carbon Fiber Circular Rails

Hithunder has leveraged advanced carbon fiber technology to create circular rails that excel in both performance and adaptability. Below are some standout features:

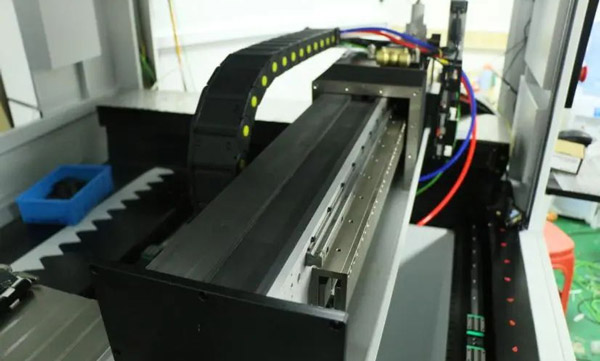

Customizable Dimensions

The standard design includes an outer diameter of 10.0 mm, inner diameter of 6.9 mm, wall thickness of 1.55 mm, and a length of 440.0 mm. These dimensions can be customized to fit specific customer requirements, ensuring compatibility with various printer models.Precision Performance for High Accuracy

The X-axis rails are optimized for fatigue resistance and deformation minimization, enabling printing accuracy of ±0.2 mm or better. This consistency in precision ensures superior output, even at higher processing speeds.Durability and Longevity

Carbon fiber’s inherent strength and fatigue resistance extend the lifespan of the rails. This durability translates to reduced maintenance requirements and long-term cost savings.High-Performance Z-Axis Engineering

The Z-axis rails are specifically designed to support heavier loads without compromising performance. This feature ensures stability for larger-scale projects while maintaining smooth movement.

Benefits of Carbon Fiber Circular Rails in 3D Printing

Carbon Fiber Circular Rails solutions offer multiple benefits for businesses and individual users of 3D printing technology:

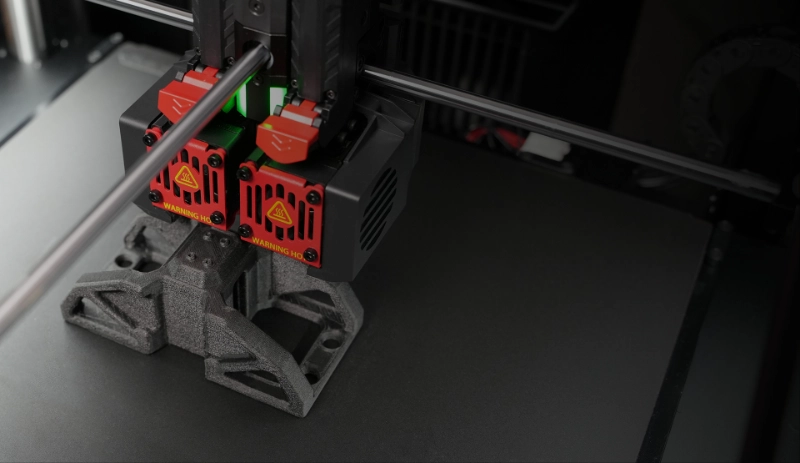

- Improved Print Quality: Reduced vibrations and enhanced stability ensure that every layer is printed with precision, minimizing defects and inconsistencies.

- Faster Printing Speeds: With reduced deflection errors and higher load capacity, printing processes can be executed at greater speeds without sacrificing accuracy.

- Energy Savings: Lighter components reduce the power consumption of 3D printers, leading to significant energy and cost savings over time.

- Competitive Edge: Businesses using Hithunder’s rails can offer higher-quality products at lower operational costs, boosting their market competitiveness.

Eco-Friendly Operations: The energy efficiency of these rails supports environmentally conscious manufacturing practices.

Applications of Carbon Fiber Circular Rails in 3D Printing

Carbon fiber rails are versatile and can be applied to various types of 3D printers, including:

- Industrial-Grade 3D Printers: For producing large-scale, complex components.

- High-Precision Printers: Where dimensional accuracy is critical, such as in aerospace, medical, or automotive applications.

Desktop 3D Printers: Offering professional-quality performance for small businesses and hobbyists.

Why Choose Hithunder for Carbon Fiber Circular Rails Solutions?

Hithunder is at the forefront of Carbon Fiber Circular Rails solutions, delivering products designed for maximum reliability and performance. Our rails not only enhance the operational efficiency of 3D printers but also ensure long-term cost-effectiveness for our clients. From customizable dimensions to energy-saving features, Hithunder’s rails are tailored to meet the evolving demands of the 3D printing industry.

Conclusion

In the competitive world of 3D printing, having the right components can make all the difference. Hithunder’s Carbon Fiber Circular Rails solutions represent a significant step forward in achieving stable, smooth, and efficient printing. Whether you’re focused on improving precision, speeding up production, or reducing costs, these innovative rails offer the perfect balance of performance and reliability.

Ready to revolutionize your 3D printing operations? Contact Hithunder today to learn more about our cutting-edge Carbon Fiber Circular Rails solutions and discover how they can elevate your 3D printing projects to the next level.