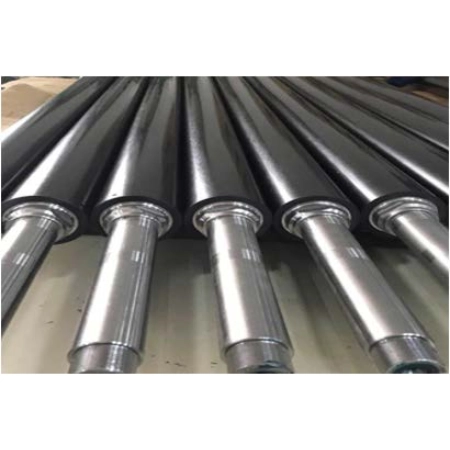

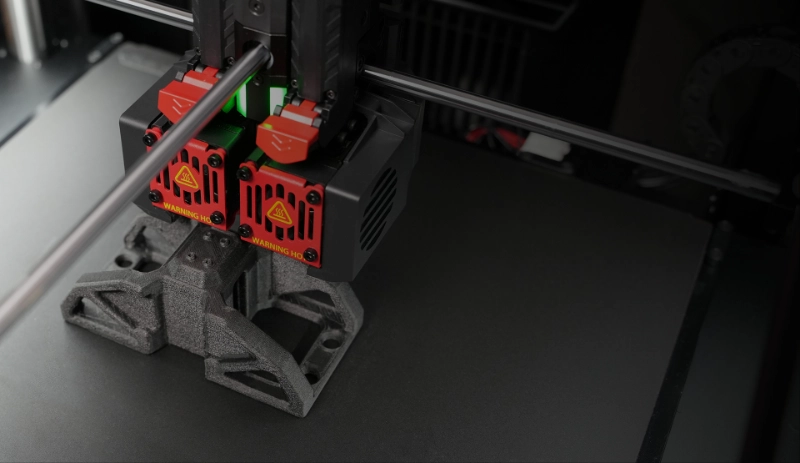

When it comes to upgrading the performance of your 3D printer, the components you choose can make all the difference. Among the most essential and impactful upgrades for enhancing precision and efficiency are carbon fiber circular rails. This advanced material provides a range of benefits, making it an ideal choice for those looking to improve their 3D printing setups. In this article, we’ll explore the top benefits of using carbon fiber circular rails in your 3D printer, with a particular focus on the features of Hithunder's Carbon Fiber Circular Rail.

1. Superior Load Capacity and Stability

One of the most important advantages of carbon fiber circular rails is their ability to support high loads while maintaining a lightweight profile. Hithunder’s Carbon Fiber Circular Rail is engineered to excel in this area. With a high load-bearing capacity in the Z-axis, it ensures that the rails can withstand the heavy demands of your printing equipment. The high strength of carbon fiber minimizes vibrations and deflection errors, allowing for smoother movements during the printing process. This stability is crucial for maintaining the accuracy of prints, especially for larger or more complex models.

2. Improved Precision for High-Quality Prints

The precision of your 3D printer directly influences the quality of your final product. Carbon fiber rails are known for their high accuracy, and Hithunder’s carbon fiber circular rails take this performance to the next level. The X-axis rails are lightweight and fatigue-resistant, meaning they exhibit minimal deformation even during extended use. This results in precision printing of ±0.2 mm or better, allowing you to produce models with exceptional detail and smooth finishes. Whether you are printing prototypes or functional parts, the precise movement of carbon fiber rails guarantees high-quality results every time.

3. Enhanced Energy Efficiency and Cost Reduction

Energy efficiency is a major consideration for businesses looking to reduce operational costs. The lightweight nature of carbon fiber technology allows Hithunder’s Carbon Fiber Circular Rail to drastically reduce the weight of the moving parts in your 3D printer. This weight reduction leads to a significant decrease in energy consumption, resulting in energy savings of 30% to 60% without compromising on print quality. Lower energy consumption not only cuts operational costs but also improves the overall environmental footprint of your 3D printing processes. This cost efficiency is a game-changer for businesses aiming to stay competitive in an increasingly cost-conscious market.

4. Customization for Tailored Applications

Every 3D printer is different, and so are the specific needs of each user. The ability to customize your equipment to meet these unique needs is an invaluable advantage. Hithunder’s carbon fiber circular rails come in standard dimensions but also offer customization options to ensure they meet your exact specifications. With an outer diameter of 10.0 mm, an inner diameter of 6.9 mm, and a wall thickness of 1.55 mm, these rails can be adapted for specific uses or requirements. The ability to modify the rails based on your unique setup ensures a perfect fit, making them a versatile choice for various 3D printing applications.

5. Durability and Long-Term Performance

Durability is another key benefit of using carbon fiber circular rails in your 3D printer. Hithunder’s Carbon Fiber Circular Rail is designed for long-term, high-precision performance, ensuring that your investment lasts. The material’s natural resistance to wear and tear, along with its fatigue-resistant properties, means fewer maintenance requirements over time. This not only reduces downtime but also extends the lifespan of your printer. As the rails maintain their precision over extended use, you can consistently rely on your printer to produce high-quality prints without the risk of degraded performance.

6. Reduced Maintenance and Downtime

Traditional 3D printer parts, particularly metal rails, are prone to wear and deformation, leading to costly repairs and extended downtime. The lightweight and durable design of carbon fiber rails ensures fewer wear-related issues, reducing the need for frequent maintenance. This results in lower operational costs and improved productivity, as the printer spends less time offline for repairs. Over the lifespan of your 3D printer, you will notice a significant reduction in downtime, translating into higher efficiency and better output.

7. Sleek and Modern Aesthetic

While performance is the primary consideration, aesthetics can also play a role in choosing the right 3D printer parts. Carbon fiber has a sleek, modern appearance that can complement the high-tech design of your 3D printer. If you’re building or upgrading a printer for professional use, the high-quality finish of carbon fiber components can also enhance the overall look and feel of the machine. Not only do carbon fiber circular rails improve the performance of your printer, but they also elevate its visual appeal.

Conclusion

Integrating carbon fiber circular rails into your 3D printer is a smart upgrade that offers a wide range of benefits. From superior load capacity and stability to improved precision, energy efficiency, and reduced maintenance, these rails are an essential component for any serious 3D printing setup. Hithunder’s Carbon Fiber Circular Rail stands out for its precision, durability, and customization options, making it an ideal choice for users looking to enhance the performance and longevity of their 3D printers.

By investing in carbon fiber technology, businesses and hobbyists alike can enjoy faster, more accurate printing with lower operational costs. Whether you’re focused on prototyping or large-scale manufacturing, the benefits of carbon fiber circular rails are clear: increased performance, reduced energy consumption, and long-term reliability. If you’re looking to take your 3D printing capabilities to the next level, carbon fiber circular rails are the key to achieving your goals.