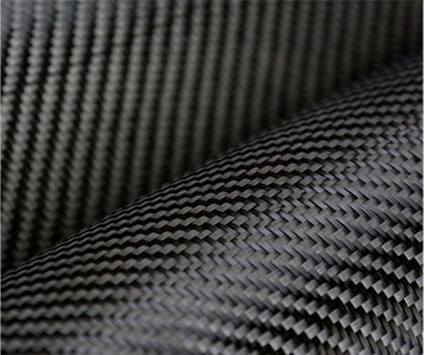

In the ever-evolving world of manufacturing, composite materials have emerged as a key driver of innovation and efficiency. Among the most notable composite materials is carbon fiber, which has revolutionized industries such as aerospace, automotive, and construction. Thanks to its exceptional strength-to-weight ratio, corrosion resistance, and versatility, carbon fiber has become a go-to material for companies seeking to enhance performance and reduce costs.

In this blog, we will explore the advantages of carbon fiber composite materials and how they are transforming modern manufacturing. We will also look at how Hithunder Composite Materials Technology, a leading high-tech company specializing in composite material development, is pushing the boundaries of innovation by integrating advanced aerospace composite technologies into the civilian market.

1. Lightweight Yet Strong: The Ultimate Material for Performance

One of the standout characteristics of carbon fiber is its lightweight nature without compromising on strength. Carbon fiber composites are significantly lighter than metals such as steel and aluminum while still providing superior strength and durability. This unique property makes carbon fiber particularly valuable in industries that demand high performance while minimizing weight, such as the aerospace and automotive sectors.

In aerospace, for example, the lightweight properties of carbon fiber composites contribute to improved fuel efficiency and enhanced performance. The same benefit applies to the automotive industry, where carbon fiber components are used in everything from chassis to body panels, reducing overall vehicle weight and improving fuel efficiency.

2. Superior Durability and Corrosion Resistance

Another significant advantage of carbon fiber composites is their exceptional durability. Unlike metals, carbon fiber is highly resistant to corrosion, which makes it ideal for use in harsh environments. This is particularly important in industries like marine, automotive, and construction, where exposure to moisture, salt, and chemicals can lead to material degradation over time.

For example, in the automotive industry, carbon fiber is used in high-performance cars that need to withstand extreme weather conditions. In the marine industry, carbon fiber composite materials are used in boat hulls and other components that must endure constant exposure to saltwater.

3. High Modulus and Excellent Fatigue Resistance

Carbon fiber composites offer excellent fatigue resistance, making them a reliable choice for applications that undergo repeated stress and strain. This quality is crucial for industries like aerospace and automotive, where components must maintain their structural integrity despite continuous vibration and movement.

In the case of aerospace, aircraft structures made from carbon fiber composites can withstand the constant pressure and strain during takeoff, landing, and flight without experiencing significant wear or failure. This allows for longer-lasting, safer, and more reliable aircraft.

4. Customization and Design Flexibility

Carbon fiber composites offer tremendous design flexibility. The material can be molded into complex shapes and structures, allowing for the creation of parts that are both lightweight and highly functional. This level of customization is particularly beneficial in industries that require specialized or aerodynamic designs, such as automotive racing, aerospace, and sports equipment manufacturing.

Hithunder Composite Materials Technology, for example, specializes in tailored composite solutions that meet the unique demands of various industries. Their expertise in adapting carbon fiber technology for specific applications allows them to provide innovative, customized components that are optimized for performance, weight, and strength.

5. Cost Efficiency in Long-Term Use

While the initial cost of carbon fiber composite materials may be higher than traditional materials, the long-term cost savings are substantial. Due to the reduced maintenance needs, longer lifespan, and improved fuel efficiency that carbon fiber offers, businesses can recoup their initial investment in a relatively short period.

For example, in the aerospace industry, the reduction in fuel consumption due to lighter aircraft directly translates to significant cost savings over the lifespan of an airplane. Similarly, in automotive manufacturing, the use of carbon fiber components can lead to a decrease in fuel consumption, lowering operating costs for consumers.

6. Hithunder Composite Materials Technology: Leading the Charge in Innovation

As a high-tech company specializing in the development and production of composite materials, Hithunder Composite Materials Technology has been at the forefront of integrating aerospace-grade composite materials into civilian applications. With a commitment to technological innovation and a strong market-oriented approach, the company has successfully bridged the gap between military technologies and civilian sectors, bringing advanced composite material solutions to industries like automotive, construction, and sports equipment.

Hithunder's expertise in research and development, along with their focus on precision engineering, has allowed them to stay ahead of the curve in an increasingly competitive market. The company’s ability to tailor solutions to meet the specific needs of their clients has made them a trusted partner for industries seeking the highest quality composite materials.

7. The Future of Carbon Fiber in Manufacturing

Looking ahead, the role of carbon fiber composites in modern manufacturing is only expected to grow. As industries continue to prioritize sustainability, fuel efficiency, and performance, carbon fiber will remain a crucial material for reducing the environmental impact of manufacturing processes.

With companies like Hithunder Composite Materials Technology pushing the boundaries of innovation, we can expect to see even more advanced and efficient uses of carbon fiber composites across diverse sectors. Whether in automotive, aerospace, or construction, carbon fiber's strength, lightness, and versatility will continue to drive technological advancement in the years to come.

Conclusion

The advantages of composite material carbon fiber are undeniable, offering businesses significant benefits in terms of strength, weight reduction, durability, and cost-efficiency. As industries continue to embrace these materials, carbon fiber composites are set to revolutionize manufacturing, driving innovation and sustainability across the globe.

Hithunder Composite Materials Technology is leading the way in introducing advanced composite solutions, ensuring industries have access to the highest-quality materials for their manufacturing needs. If you’re looking to integrate carbon fiber into your products, consider partnering with a trusted and innovative supplier like Hithunder to take your designs to the next level.