Applications of Vacuum Chucks

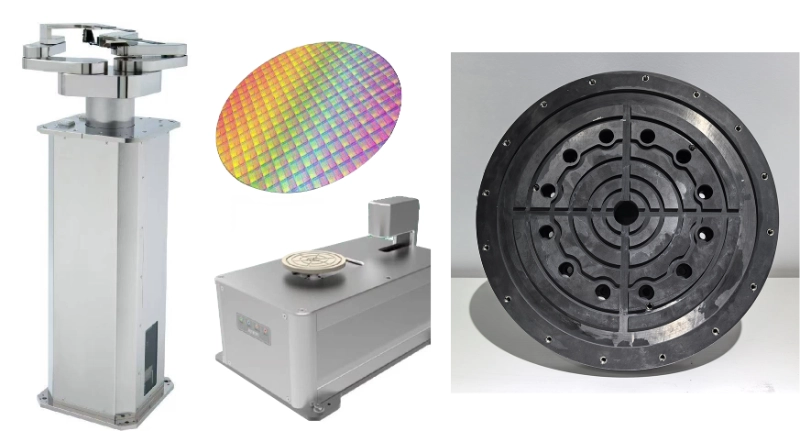

Vacuum chucks are versatile tools widely used across various industries due to their ability to lift and move objects securely and efficiently. Common applications include:

1. Manufacturing: Used for handling glass, metal sheets, and plastic components during assembly and production processes.

2. Automotive: Essential for lifting and positioning windshields and body panels in vehicle assembly lines.

3. Packaging: Employed in automated packaging systems to pick and place products with precision.

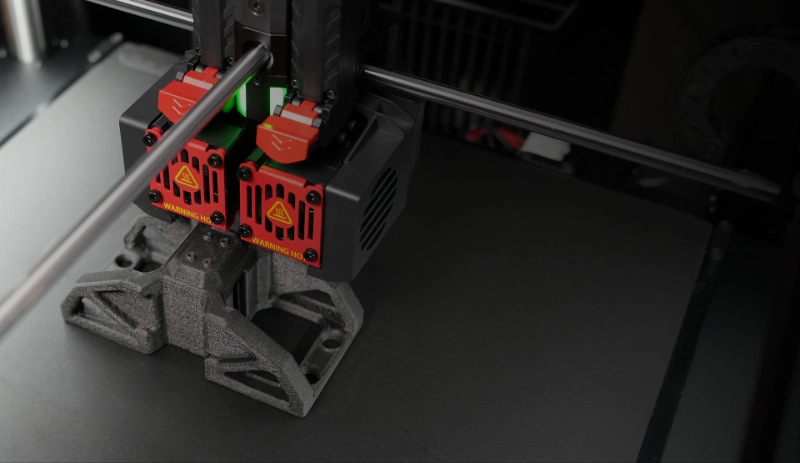

4. Robotics: Integral in robotic arms for material handling, allowing for the safe transport of delicate or heavy items.

5. Food Industry: Utilized in packaging and processing to handle food products without contamination.

Materials Used in Vacuum Chucks

Vacuum Chucks can be made from various materials, each with its own advantages and limitations:

1. Rubber: Commonly used due to its flexibility and good grip. However, it can wear out quickly and may not be suitable for high-temperature applications.

2. Silicone: Offers excellent temperature resistance and durability. Silicone cups are generally more resistant to wear but can lack the same grip as rubber.

3. Polyurethane: Known for its strength and abrasion resistance, polyurethane cups are suitable for heavy lifting but can be heavier than other materials.

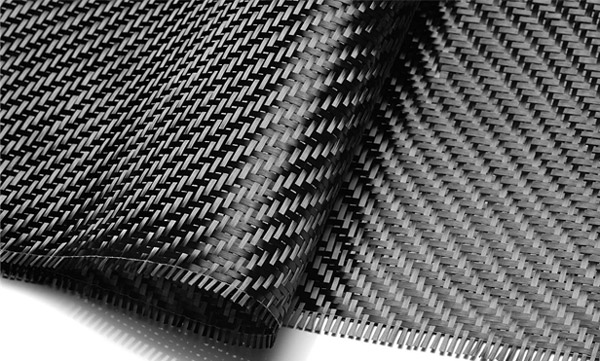

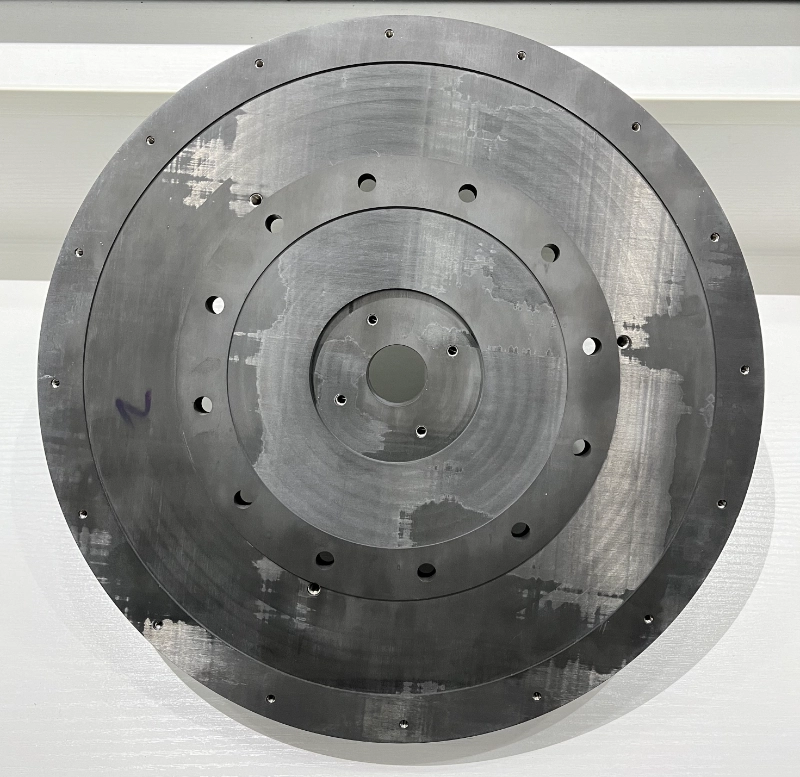

4. Carbon Fiber: A lightweight, high-strength material that combines durability with minimal weight, making it ideal for applications requiring both strength and efficiency.

Advantages of Hithunder's Carbon Fiber Vacuum Chucks

Hithunder has recently launched its innovative Carbon Fiber Vacuum Chucks, which stand out in several key areas compared to traditional materials:

1. Weight Reduction: Carbon fiber cups are significantly lighter than rubber or polyurethane options. This weight reduction leads to less strain on machinery and improved handling efficiency.

2. High Load Capacity: Despite their lightweight nature, carbon fiber cups offer exceptional strength, allowing them to handle heavy loads without deformation.

3. Durability: Carbon fiber is highly resistant to wear and tear, increasing the lifespan of the Chucks compared to rubber and silicone, which can degrade over time.

4. Temperature Resistance: Carbon fiber can withstand higher temperatures without losing its structural integrity, making it suitable for a wider range of applications.

5. Precision and Stability: The rigidity of carbon fiber ensures that the cups maintain their shape under load, providing consistent performance and reliable grip.

Conclusion

Hithunder's Carbon Fiber Vacuum Chucks represent a significant advancement in material handling technology. By combining the lightweight and durable properties of carbon fiber with the practical applications of vacuum suction technology, these cups offer unparalleled performance in various industries. As businesses seek to improve efficiency and reduce operational costs, our carbon fiber Chucks are positioned as a superior alternative to traditional rubber, silicone, and polyurethane options.

Choosing Hithunder means investing in innovative solutions that enhance productivity, reliability, and competitiveness in the market.