In today's rapidly evolving manufacturing world, the demand for strong, lightweight, and durable materials has never been higher. Among these materials, carbon fiber composite stands out as one of the most advanced and efficient options. With its incredible combination of strength, durability, and versatility, carbon fiber has found its place in a wide range of industries, from aerospace and automotive to sports equipment and construction.

In this blog, we will dive into the strength and durability of carbon fiber composites, explaining why this material is essential for modern manufacturing. We’ll also highlight how Hithunder Composite Materials Technology, a leading company in composite material development, has contributed to pushing the boundaries of carbon fiber innovation and adapting aerospace technologies for civilian use.

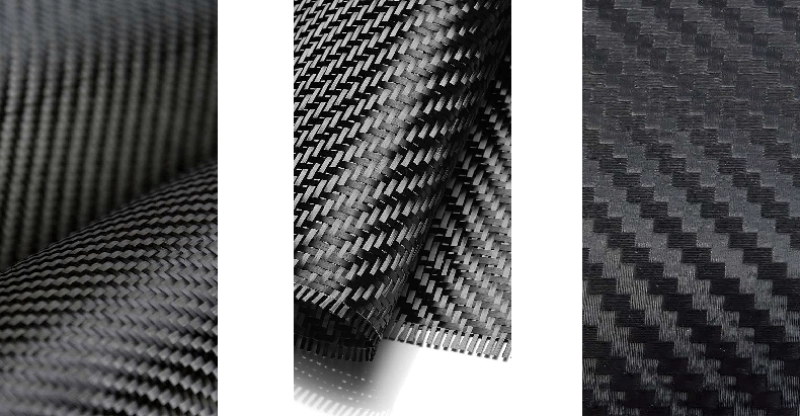

1. The Strength of Carbon Fiber Composites

Exceptional Strength-to-Weight Ratio

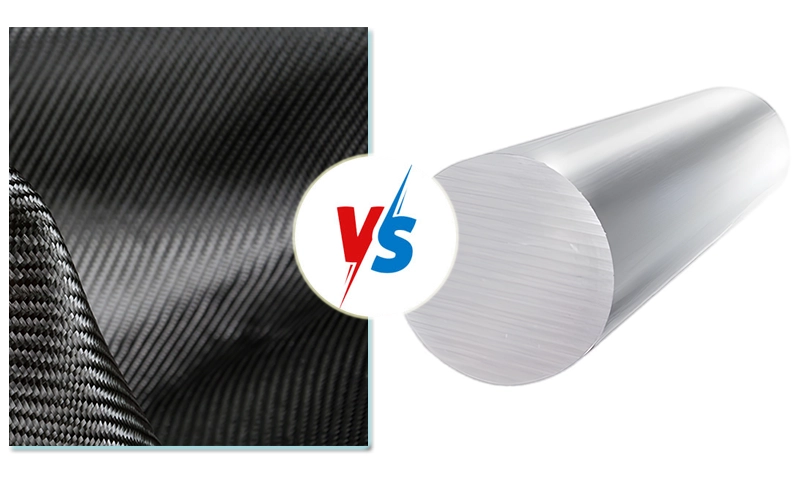

The most remarkable feature of carbon fiber composites is their strength-to-weight ratio. Carbon fiber is often used as a substitute for metals like steel and aluminum because it provides a superior balance of strength and lightness. In fact, carbon fiber is about five times stronger than steel, yet it is much lighter. This makes it ideal for industries that require high-strength materials without adding unnecessary weight.

For example, in the aerospace industry, carbon fiber is used to create structural components like aircraft wings, fuselages, and tail sections. The reduced weight of these components not only improves fuel efficiency but also enhances the overall performance of aircraft. Similarly, in the automotive industry, carbon fiber is used for car bodies and engine parts, improving speed, acceleration, and fuel efficiency while maintaining structural integrity.

High Tensile Strength

Tensile strength refers to a material's ability to resist tension or stretching. Carbon fiber composites excel in this area, providing superior resistance to forces that would typically stretch or break other materials. This makes them particularly valuable for industries that require materials capable of withstanding high-stress situations, such as spacecraft, military vehicles, and high-performance vehicles.

The high tensile strength of carbon fiber ensures that components can endure extreme forces without cracking or breaking. For example, in automotive racing, carbon fiber is used in car chassis and safety structures, which need to withstand not only the rigorous driving conditions but also any impact forces in the event of a crash.

2. Durability of Carbon Fiber Composites

Resistance to Corrosion

Carbon fiber composites are known for their resistance to corrosion. Unlike metals such as steel, which can rust when exposed to moisture or harsh environmental conditions, carbon fiber does not suffer from corrosion. This feature makes it ideal for applications in marine environments, where saltwater can rapidly degrade other materials, and in outdoor applications, where components are exposed to the elements.

For example, marine vessels and offshore platforms are increasingly using carbon fiber to build hulls and structural components. These parts last longer and require less maintenance, saving on long-term costs. Similarly, in construction, carbon fiber is used to reinforce concrete structures and steel beams, enhancing their durability against environmental factors like moisture, UV rays, and temperature fluctuations.

Impact Resistance

Another impressive characteristic of carbon fiber composites is their impact resistance. Despite being lightweight, carbon fiber can absorb and dissipate energy from impacts without cracking or breaking. This makes it ideal for industries where components must be able to withstand sudden impacts or collisions, such as in the automotive and sports equipment industries.

For example, helmet manufacturers use carbon fiber to produce high-performance helmets that can absorb the shock of an impact, protecting the wearer from injury. In sports equipment, carbon fiber is used in items like bicycles, skis, and golf clubs, where durability and strength are essential for safety and performance.

Fatigue Resistance

Fatigue resistance refers to a material's ability to withstand repeated stress and strain without failing. Carbon fiber composites exhibit outstanding fatigue resistance, making them ideal for applications where parts will undergo constant use, such as in automobiles, aircraft, and machinery. The long-term durability of carbon fiber components reduces the frequency of repairs or replacements, resulting in cost savings for industries.

In the aviation industry, for example, aircraft made with carbon fiber composites experience less wear and tear over time, leading to fewer maintenance requirements and increased aircraft lifespan. Similarly, in automotive manufacturing, the use of carbon fiber in brake pads, springs, and shock absorbers helps to enhance the performance and longevity of vehicles.

3. Hithunder Composite Materials Technology: Innovation in Carbon Fiber

Hithunder Composite Materials Technology has been at the forefront of composite material development for over two decades. The company specializes in high-performance composite components, using advanced aerospace composite technologies that have been integrated into civilian applications. By combining technical innovation with market demand, Hithunder brings cutting-edge carbon fiber solutions to industries like automotive, aerospace, and construction.

As a high-tech company, Hithunder remains dedicated to research and development, ensuring that each product is optimized for strength, durability, and performance. The company’s ability to customize solutions to meet the specific needs of clients allows them to create tailored carbon fiber components that perform beyond expectations.

Their commitment to military-to-civilian technology transfer has helped push the boundaries of carbon fiber applications, bringing aerospace-grade materials to industries that require high-performance materials without compromising on cost-effectiveness.

4. Future Applications and Innovations in Carbon Fiber

The strength and durability of carbon fiber composites make them a critical material for the future of manufacturing. As industries continue to focus on performance, lightweight design, and sustainability, carbon fiber will play an increasingly important role in developing the next generation of high-performance products.

At Hithunder Composite Materials Technology, the innovation doesn’t stop at just strength and durability. The company is constantly working to explore new applications for carbon fiber, pushing the limits of what this material can achieve. As carbon fiber technology continues to evolve, we can expect to see even more cutting-edge uses across a range of sectors, from green building materials to electric vehicles and space exploration.

5. Conclusion

The strength and durability of carbon fiber composites make them an indispensable material in modern manufacturing. Whether it’s for aerospace, automotive, or construction, the ability of carbon fiber to offer a combination of lightness, strength, corrosion resistance, and impact resistance makes it the material of choice for industries that require top-tier performance.

With companies like Hithunder Composite Materials Technology leading the charge, the future of carbon fiber technology is brighter than ever. Through continuous innovation and market-driven solutions, carbon fiber will continue to shape the future of manufacturing, delivering sustainable, high-performance materials that meet the demands of today and tomorrow.