The demand for high-performance, durable, and lightweight materials in the medical equipment industry has never been higher. One material that is gaining significant attention for its exceptional properties is carbon fiber composite. Carbon fiber composite materials, known for their high strength-to-weight ratio, durability, and resistance to wear, are transforming the design and functionality of medical devices. In this article, we will explore how carbon fiber composites improve the durability and performance of medical equipment, with insights from Hithunder Composite Materials Technology, a leading company in the research, development, and production of advanced composite materials.

1. Superior Strength and Durability

One of the most notable advantages of carbon fiber composite materials is their remarkable strength. Carbon fiber composites are incredibly strong yet lightweight, making them ideal for medical devices that require high durability without adding excess weight. For instance, components like surgical tools, prosthetics, and imaging devices benefit from the added strength of carbon fiber, which helps prevent wear and tear over time.

Hithunder Composite Materials Technology, which has a rich history of applying aerospace-grade composite technologies to civilian industries, ensures that their carbon fiber materials are designed to withstand the rigors of medical environments. By introducing these advanced materials to the medical field, they help enhance the longevity and performance of medical equipment, reducing the need for frequent replacements or repairs.

2. High Resistance to Corrosion and Chemical Damage

Medical equipment is often exposed to harsh cleaning chemicals, sterilization processes, and corrosive environments. Traditional materials may degrade or weaken over time when subjected to such conditions. Carbon fiber composites, however, are highly resistant to corrosion and chemical damage, making them an ideal choice for medical devices that require frequent sterilization and exposure to various substances.

The corrosion resistance of carbon fiber composites ensures that medical devices maintain their integrity and reliability, even after prolonged exposure to cleaning agents, high temperatures, or moisture. This durability helps extend the lifespan of the equipment and enhances patient safety by ensuring that devices are less prone to degradation and failure.

3. Lightweight for Improved Handling and Comfort

The lightweight nature of carbon fiber composites is a game-changer for the medical device industry. Lighter equipment improves user experience, whether it's for healthcare professionals handling surgical instruments or patients wearing prosthetic limbs. By reducing the weight of medical devices, carbon fiber composites help alleviate strain and discomfort, ultimately improving the overall usability and functionality of medical equipment.

For example, carbon fiber prosthetics and orthotics provide patients with a more comfortable and natural feel compared to traditional metal counterparts. The material’s lightweight nature also allows for more precise design, ensuring that devices can be customized for better fit and comfort.

4. Enhanced Biocompatibility for Medical Use

Another critical factor in the medical industry is the biocompatibility of materials. Devices that come into contact with the human body need to be safe, non-toxic, and capable of withstanding biological environments without causing adverse reactions. Carbon fiber composites can be engineered with high levels of biocompatibility, making them suitable for implants, prosthetics, and surgical tools.

Hithunder Composite Materials Technology leverages its experience in aerospace materials to develop carbon fiber composites that meet the stringent standards of the medical field. These composites are designed to integrate seamlessly with human tissue, minimizing the risk of rejection or irritation and promoting better outcomes for patients.

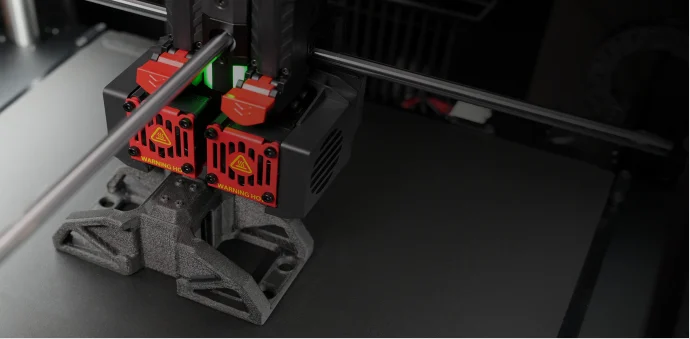

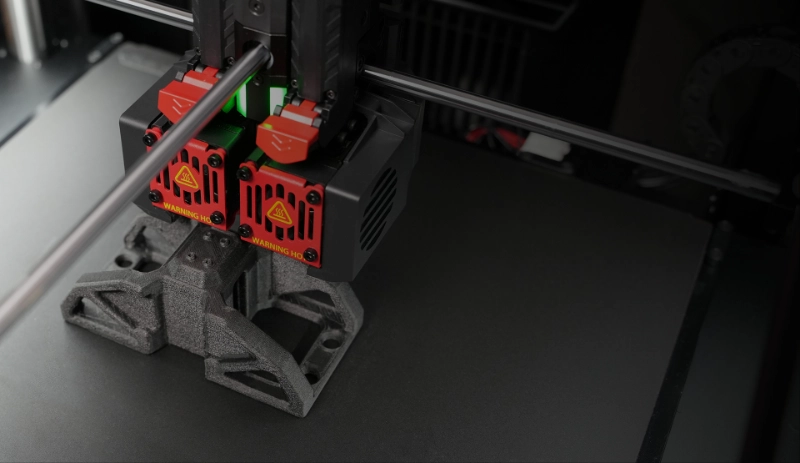

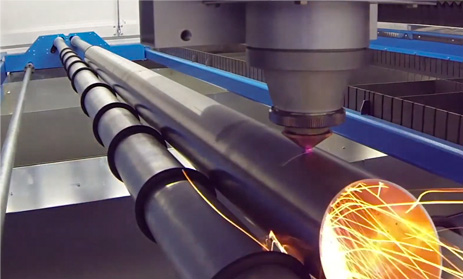

5. Design Flexibility and Precision

Carbon fiber composites offer unmatched design flexibility, allowing manufacturers to create complex shapes and structures that would be difficult or impossible with traditional materials. This flexibility enables the production of medical devices with intricate geometries, enhancing functionality and performance.

For instance, the ability to create precise and lightweight components for imaging devices, surgical instruments, and diagnostic tools leads to more efficient operations and higher accuracy in procedures. Additionally, the ability to tailor the material’s properties—such as stiffness, strength, and flexibility—allows for the creation of custom medical solutions for specific patient needs.

Hithunder Composite Materials Technology’s focus on innovation ensures that their composite materials are at the forefront of design and production. By introducing cutting-edge composite technologies to the medical field, they enable manufacturers to produce devices that are not only functional but also optimized for performance.

6. Improved Safety and Reliability

Safety and reliability are paramount in the medical field. Carbon fiber composites play a significant role in improving the safety of medical devices by providing enhanced strength and resistance to breakage. In critical applications, such as surgical tools or equipment used in emergency situations, the reliability of the materials is crucial.

Carbon fiber composites are engineered to perform well under stress and extreme conditions, ensuring that medical devices remain intact and functional even in high-pressure environments. The material's resistance to fatigue also ensures that components maintain their structural integrity over time, reducing the likelihood of failure during use.

Conclusion: The Future of Medical Equipment with Carbon Fiber Composites

The integration of carbon fiber composite materials in the medical equipment industry offers numerous advantages, including increased durability, enhanced performance, and improved patient outcomes. With their strength, lightweight properties, corrosion resistance, and biocompatibility, carbon fiber composites are transforming the design and functionality of medical devices, making them more reliable, efficient, and patient-friendly.

Hithunder Composite Materials Technology continues to lead the way in advancing composite material technologies, ensuring that the medical industry has access to the most innovative and high-performing materials available. By applying aerospace-grade composite solutions to medical equipment, they are helping to enhance the durability, performance, and safety of medical devices, ultimately contributing to better healthcare and patient care worldwide.

If you are looking to improve the durability, performance, and reliability of your medical devices, consider the use of carbon fiber composites. With the expertise of companies like Hithunder, the future of medical equipment is set to be lighter, stronger, and more efficient than ever before.