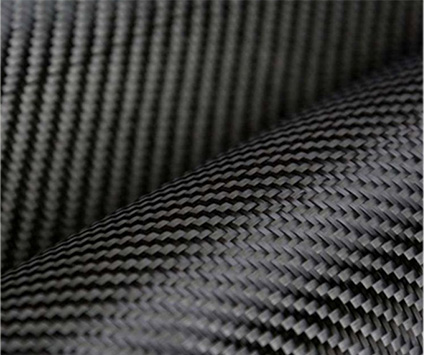

The construction and engineering industries have always been driven by the need for materials that offer strength, durability, and versatility. With the growing demand for sustainable, high-performance, and cost-effective solutions, carbon fiber beams have emerged as one of the most innovative materials of the future. Offering unparalleled advantages over traditional construction materials, carbon fiber beams are poised to revolutionize the way buildings, bridges, and infrastructure are designed and built.

In this article, we’ll explore why carbon fiber beams are the future of construction and engineering and how companies like Hithunder Composite Materials Technology, with their deep expertise in aerospace-grade composite materials, are playing a key role in bringing these high-performance solutions into the civilian sector.

1. Superior Strength-to-Weight Ratio

One of the standout advantages of carbon fiber beams is their unmatched strength-to-weight ratio. Traditional construction materials like steel and concrete are known for their strength, but they also come with the downside of being heavy. Carbon fiber, on the other hand, provides incredible strength while being much lighter than steel or other metal alloys. This makes carbon fiber beams ideal for applications where reducing weight is crucial—such as in high-rise buildings, bridges, and even aerospace structures.

The lighter weight of carbon fiber beams also allows for easier transportation and installation, reducing labor costs and time on-site. This is particularly beneficial in projects with tight deadlines and where minimizing disruption is essential. Hithunder Composite Materials Technology, a leading expert in composite materials, has developed carbon fiber solutions that integrate aerospace-grade technology, making them suitable for a wide range of construction and engineering applications.

2. Durability and Longevity

Another key advantage of carbon fiber beams is their exceptional durability. Unlike traditional materials like steel, which can corrode or degrade over time, carbon fiber beams are highly resistant to moisture, chemicals, and environmental factors. This corrosion resistance makes them ideal for long-term applications in harsh environments, including coastal regions, industrial plants, and other corrosive settings.

In addition to being resistant to rust and corrosion, carbon fiber beams also withstand extreme temperatures, UV radiation, and other environmental factors that can cause other materials to weaken or fail. This means that structures made with carbon fiber beams are low maintenance and have a significantly longer lifespan, making them a wise investment for the future.

Hithunder Composite Materials Technology continues to bring advanced aerospace technologies to civilian construction and engineering applications, ensuring that their carbon fiber products meet the highest standards of durability and performance.

3. Design Flexibility and Customization

The versatility of carbon fiber beams goes beyond their strength and durability. Carbon fiber is highly flexible and can be molded into virtually any shape or size, offering immense design freedom. Whether for complex architectural designs, innovative bridges, or precision engineering in automotive and aerospace sectors, carbon fiber beams provide unmatched customization options.

With Hithunder's advanced manufacturing capabilities, engineers and architects can work with a material that can be tailored to meet the exact specifications of their projects. The ability to create lightweight, strong beams that fit precisely into a design gives architects the flexibility to push the boundaries of what is possible in modern construction.

4. Energy Efficiency and Sustainability

As the world becomes increasingly focused on sustainability, carbon fiber beams play a key role in achieving more energy-efficient buildings and infrastructure. Their lightweight nature reduces the overall energy required during transportation, installation, and even the long-term maintenance of the structure. Additionally, carbon fiber beams can help reduce the overall energy consumption of buildings by allowing for better heat retention and improved insulation properties.

By using carbon fiber in construction, the energy footprint of a building can be dramatically reduced, leading to lower heating and cooling costs over time. Hithunder Composite Materials Technology focuses on energy-efficient composite materials, ensuring that their carbon fiber beams not only provide superior strength but also contribute to a greener, more sustainable future.

5. Reduced Maintenance Costs

One of the major ongoing expenses in construction is the maintenance of structures. Materials like steel and concrete often require frequent inspections, repairs, and treatments to prevent damage from corrosion, wear, and environmental exposure. Carbon fiber beams, however, require minimal maintenance. Their corrosion-resistant properties and ability to withstand harsh conditions mean that structures built with carbon fiber require far less upkeep over time.

This reduction in maintenance costs makes carbon fiber beams an economically attractive solution for construction and engineering projects. The durability and longevity of carbon fiber beams allow businesses and government agencies to invest in infrastructure that will last without the need for constant repair and maintenance, ultimately lowering lifetime costs.

6. Cost-Effectiveness in the Long Run

While the initial cost of carbon fiber beams may be higher than traditional materials like steel or concrete, the long-term benefits far outweigh the upfront investment. With their strength, durability, and reduced maintenance costs, carbon fiber beams offer excellent value for money over the life of a structure. The reduced need for repairs, longer lifespan, and energy efficiency translate into savings over time.

For example, in industries like aerospace, automotive, and civil engineering, the use of carbon fiber beams can lead to lower operating costs, improved efficiency, and better overall performance. Hithunder Composite Materials Technology offers cost-effective carbon fiber solutions, making these advanced materials more accessible to a wider range of industries.

7. Military to Civilian Applications

A unique aspect of Hithunder Composite Materials Technology is its ability to bring military-grade technologies to civilian applications. The company has extensive experience in developing composite materials for military and aerospace industries and has successfully adapted these technologies for use in civilian construction and engineering projects. This transfer of technology from the military to civilian sectors brings cutting-edge solutions to a wide range of industries, ensuring that the highest standards of quality and performance are met.

By harnessing the latest aerospace composite technologies, Hithunder provides carbon fiber beams that offer not only superior performance but also cutting-edge innovation that can give your project a competitive edge.

Conclusion

As the demand for sustainable, durable, and cost-effective solutions in construction and engineering continues to rise, carbon fiber beams are positioned to lead the way into the future. Their strength, durability, energy efficiency, and flexibility make them a game-changer in industries ranging from aerospace to civil engineering and automotive manufacturing.

With over 20 years of experience in the field, Hithunder Composite Materials Technology is at the forefront of bringing advanced composite materials to the civilian sector. Their commitment to innovation and aerospace-grade technology ensures that carbon fiber beams will play a key role in shaping the future of construction and engineering for years to come.

By choosing carbon fiber beams from Hithunder, you are not just investing in a material—you are investing in the future of construction, offering a sustainable, cost-effective, and high-performance solution that will transform your projects and ensure they stand the test of time.