Introduction:

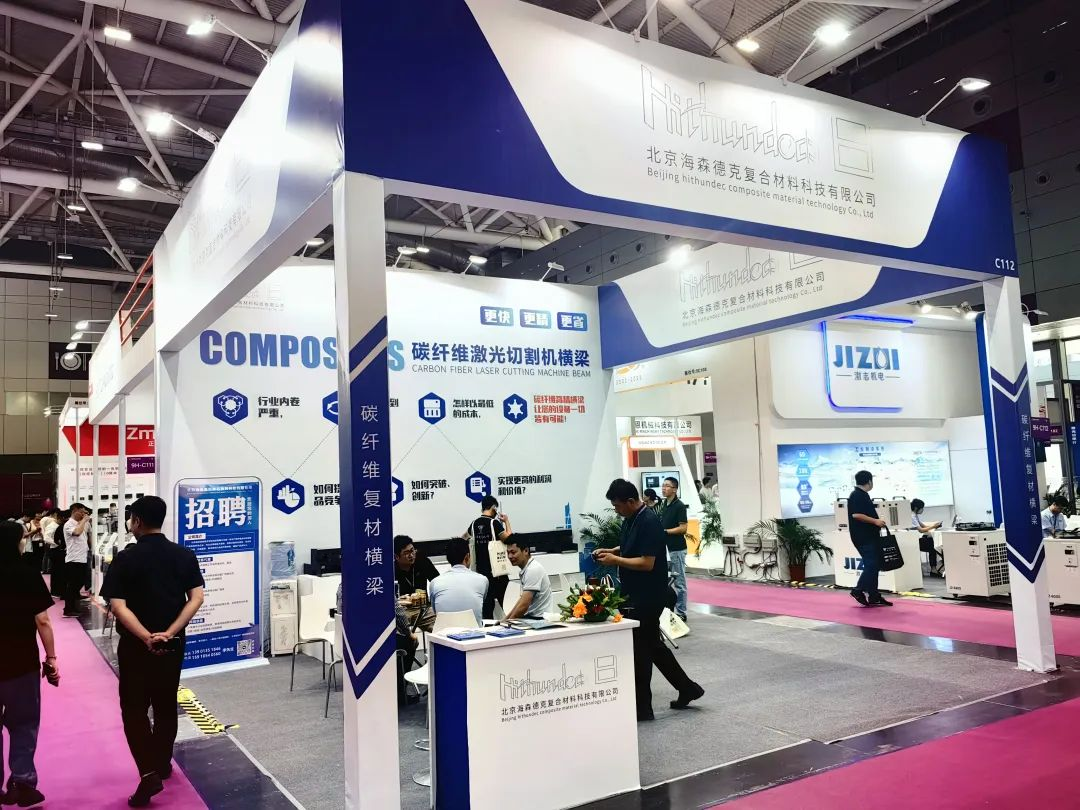

The Shenzhen International Laser & Smart Equipment and Photoelectric Technology Expo (LASERFAIR 2023), a prominent annual event in the South China region's laser and optoelectronics industry, opened its doors from June 27 to 29 at the Shenzhen World Exhibition & Convention Center (Bao'an New Hall). Amidst a market where laser power has soared to 60,000 watts, Beijing Hithunder Composite Materials Technology Co., Ltd. (Hithunder) presented a 'black technology' solution that enhances laser processing efficiency without the need for increased power: the carbon fiber beam.

The Challenge of Power Limitation:

In the past, boosting processing efficiency was straightforward: increase power. However, with the release of 60,000-watt laser cutting machines, discussions have arisen about whether further power increases are beneficial or necessary. Wu Rangda, the President of Penta Laser, believes that 60,000 watts are sufficient to replace plasma and flame cutting entirely. Higher power contributions to efficiency and capability are diminishing, while costs and energy consumption rise.

Hithunder's Solution:

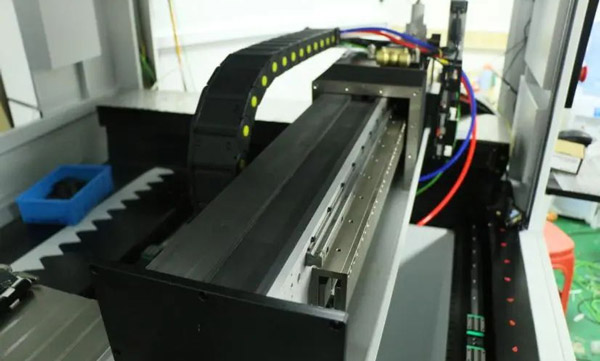

Hithunder's participation in LASERFAIR 2023 showcased the carbon fiber beam as a solution to this challenge, aiming to propel laser processing efficiency to new heights. The beam, a critical component of gantry machine tools, dictates the machine's performance, impacting efficiency, precision, and stability.

Traditional steel beams, while stable and precise, are heavy and typically used in machines where speed is not a priority. High-speed and high-acceleration require powerful motors, which can be limited by dynamic performance matches. Aluminum beams, though lighter, are still heavy, limit speed and acceleration improvements, and are susceptible to deformation and temperature changes, necessitating frequent recalibration.

Advantages of Carbon Fiber Beams:

Carbon fiber beams offer a combination of high rigidity, toughness, and lightweight design, leading to significant speed enhancements in practical applications.

Lightweight Design: The reduced weight of carbon fiber beams lowers the requirements for transmission components and motors, enabling higher speeds and accelerations with ordinary motors.

Precision and Stability: Carbon fiber's inherent properties contribute to maintaining high precision and operational stability.

Cost-Effectiveness: The use of carbon fiber can reduce costs associated with the machine base, rack, and motor systems while achieving the same acceleration performance.

Durability: Lighter beams reduce wear on guide rails and racks, extending their service life and that of the equipment.

Resilience to Accidental Damage:

Carbon fiber's composition, being inorganic and brittle, allows for elastic deformation without permanent damage. In the event of control system failures or external collisions, carbon fiber beams can rebound to their original state without permanent deformation, unlike metal materials that can suffer permanent deformation requiring replacement.

Conclusion and Future Outlook:

Hithunder's display at LASERFAIR 2023 highlights the company's commitment to advancing the laser processing industry with innovative materials and technologies. The carbon fiber beam is set to revolutionize the industry by offering a cost-effective and high-performance alternative to traditional metal beams.

Visitors to the expo can learn more about Hithunder's offerings at Booth C112 in Hall 9, where the professional team will provide detailed product introductions and answer inquiries.

As the laser technology permeates various industrial applications, Hithunder looks forward to continued face-to-face exchanges, exploring collaboration opportunities, and driving the development of the laser processing industry together.