In today's rapidly developing science and technology, the laser industry, as an important part of advanced manufacturing, is experiencing unprecedented changes and challenges. With the increasingly fierce market competition, the phenomenon of industry involution has become more and more obvious. Traditional laser cutting machines are facing multiple pressures such as high precision, high efficiency and low cost, and they are in urgent need of finding new ways to break through. At this time, the introduction of carbon fiber beam technology has brought new opportunities for cost reduction and efficiency improvement to the laser industry, and opened a new chapter in the growth curve.

Current situation of involution: double squeeze of efficiency and cost

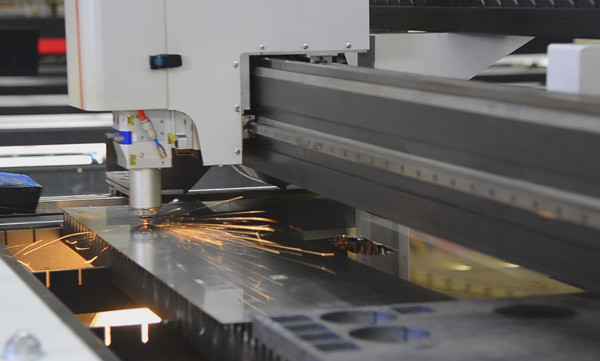

In recent years, laser cutting machines have been widely used in aerospace, automobile manufacturing, electronic communications and other fields due to their high precision and high efficiency. However, with the intensification of market competition, customers have higher and higher requirements for laser cutting machines, which not only need to ensure cutting accuracy and efficiency, but also reduce costs, which poses a severe challenge to laser equipment manufacturers.

Most traditional laser cutting machines use metal beams. Although they meet the processing requirements to a certain extent, the metal beams are heavy, have low acceleration, high energy consumption, and are difficult to ensure stability under long-term operation. These have become key factors restricting the performance improvement and cost reduction of laser cutting machines. Therefore, how to achieve cost reduction and efficiency improvement while ensuring cutting quality has become an urgent problem to be solved in the laser industry.

Solution: Carbon fiber beams lead technological innovation

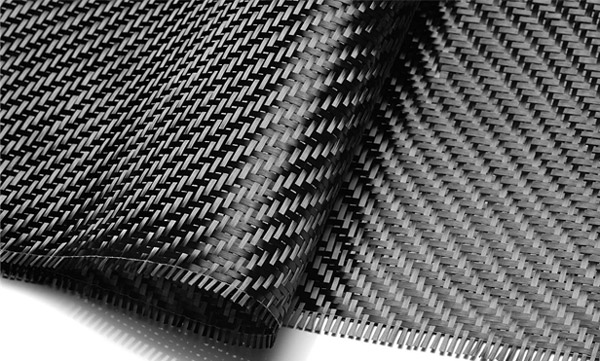

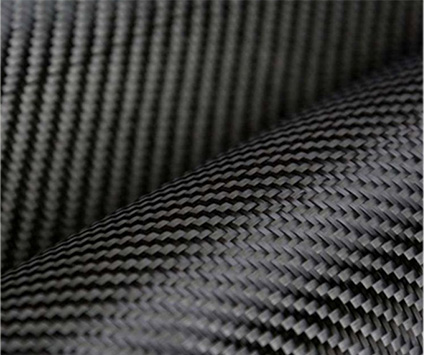

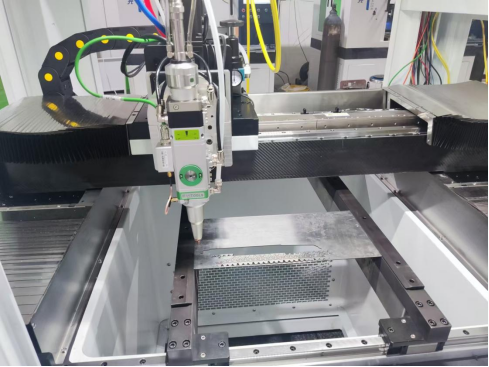

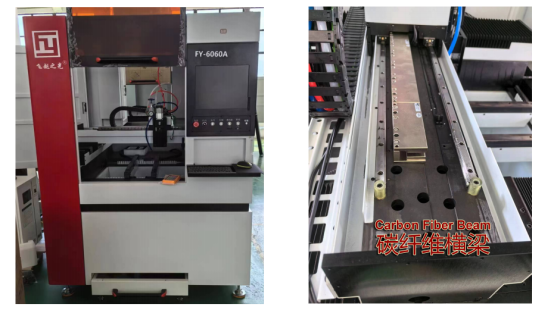

Facing the current situation of industry involution, some forward-looking laser equipment manufacturers have begun to explore new technical paths, and carbon fiber beam technology has emerged in this context. As a high-performance material, carbon fiber has excellent properties such as light weight, high strength, low thermal expansion coefficient, and corrosion resistance. Applying it to the beam of a laser cutting machine can significantly improve the performance and stability of the machine.

At present, many laser companies have begun to adopt carbon fiber beams, successfully achieving a significant increase in machine acceleration, while reducing energy consumption and after-sales costs. For example, the new generation of stainless steel laser cutting machines developed by Feiyue Laser, after adopting carbon fiber beams, the acceleration has increased from 1g to 2g, ensuring long-term um-level processing accuracy, and the after-sales cost has also been greatly reduced; and the airbag laser cutting machine developed by Han's Yueming Laser Group, with the advantages of carbon fiber beams, the acceleration has soared to 6g, and the weight of the beam has also been reduced from 170KG to 60KG, and it can maintain stable operation for a long time at 4g. These technological breakthroughs not only improve production efficiency, but also significantly reduce costs, bringing tangible profit growth to laser equipment manufacturers.

Cost reduction and efficiency improvement: the far-reaching impact of carbon fiber beams

Although the procurement cost of carbon fiber beams is relatively high, in the long run, the overall cost reduction and profit increase it brings are obvious. On the one hand, the lightweight and high-strength characteristics of carbon fiber beams reduce the energy consumption and wear of the machine, extend the service life of the equipment, and reduce maintenance costs; on the other hand, the high-performance cutting quality and efficiency improve customer satisfaction and loyalty, and win more market share and profit space for laser equipment manufacturers.

More importantly, the introduction of carbon fiber beam technology has brought a new growth curve to the laser industry. With the continuous maturity of technology and the continuous expansion of applications, carbon fiber beams will become the mainstream configuration of laser cutting machines, driving the entire industry to a higher level and wider field.

Conclusion: Innovation drives the future

In the involutionary wave of the laser industry, the introduction of carbon fiber beam technology has undoubtedly brought new hope to the industry. It not only solves the performance bottleneck and cost problems faced by traditional laser cutting machines, but also opens a new chapter of cost reduction and efficiency improvement for laser equipment manufacturers. In the future, with the continuous innovation of technology and the deepening of its application, the laser industry will usher in a broader development prospect and contribute more wisdom and strength to the transformation and upgrading of the advanced manufacturing industry.