In modern manufacturing, dispensing machines, as key equipment for precision assembly and processing, are widely used in electronics, automobiles, aerospace, medical and other fields. In 2023, the total output value of China's dispensing machine industry has reached tens of billions of yuan and maintained a steady growth trend. With the improvement of automation and intelligence in the manufacturing industry and the rapid development of emerging fields, the demand for dispensing machines continues to grow and the market scale continues to expand. It is expected that the annual compound growth rate of China's dispensing machine market will remain at a high level in the next few years, bringing broad development space for the industry.

Challenges and demands of the glue dispensing machine industry

Although the market development trend is positive, with the intensification of market competition, enterprises have put forward higher requirements for the accuracy, efficiency, stability and maintenance cost of glue dispensing machines.

In the glue dispensing operation, accurate control of the amount, position and shape of glue is the key to ensuring product quality. Traditional glue dispensing machine beams are mostly made of steel beams or aluminum beams. Although these materials have certain strength and stability, their disadvantages such as heavy weight, high thermal expansion coefficient and easy fatigue gradually emerge when facing high-precision and high-efficiency production requirements. Therefore, finding a lighter, more stable and more durable beam material has become an urgent problem to be solved in the glue dispensing machine industry.

In this context, Hithunder has launched a carbon fiber beam designed for dispensing machines with its deep accumulation of carbon fiber technology, bringing revolutionary changes to the dispensing machine industry.

Carbon fiber beam: a new leap in dispensing machine performance

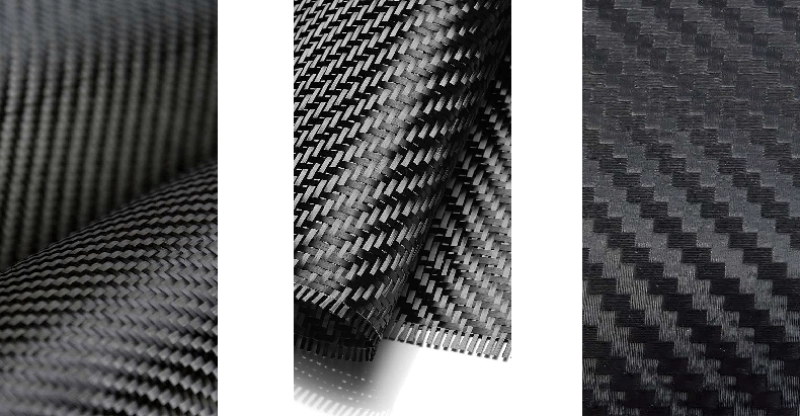

The carbon fiber beam launched by Hithunder has perfectly solved this problem in the dispensing machine industry with its unique advantages. As a high-performance material, carbon fiber has the characteristics of low density, high strength, high modulus, low thermal expansion coefficient, and fatigue resistance. These characteristics make the carbon fiber beam perform well in the application of dispensing machines:

Lightweight design: improve movement flexibility and response speed

Traditional dispensing machine beams mostly use steel beams or aluminum beams. Although these materials have certain strength and stability, their weight is large, which limits the movement speed and flexibility of the equipment. The introduction of carbon fiber beams has completely changed this situation. Compared with traditional materials, the weight of carbon fiber beams is greatly reduced, which makes the dispensing machine smoother and more responsive when performing high-speed movement. The lightweight design not only improves production efficiency, but also reduces energy consumption, saving operating costs for enterprises.

High rigidity and stability: ensuring accuracy and repeatability

The accuracy of dispensing operations is one of the important indicators for evaluating equipment performance. Carbon fiber beams provide rigidity and stability similar to steel with their excellent mechanical properties, especially the high modulus of more than 230GPa. This means that in high-speed and high-precision dispensing operations, carbon fiber beams can effectively resist deformation and ensure the accuracy and repeatability of the dispensing process. This feature is of great significance for improving product quality and reducing scrap rates, thus bringing direct economic benefits to enterprises.

Anti-thermal expansion performance: maintaining long-term accuracy

In industrial production environments, temperature changes often affect the accuracy of equipment. Carbon fiber materials, due to their extremely low thermal expansion coefficient, enable the beam to maintain good dimensional stability in an environment with temperature changes. This feature is crucial to maintaining the long-term accuracy of the dispensing machine, avoiding calibration and adjustment caused by temperature fluctuations, and further reducing maintenance costs and time.

Fatigue resistance: extending equipment life and reducing maintenance

Carbon fiber beams not only have high strength and rigidity, but also show excellent fatigue resistance. In long-term dispensing operations, the deformation of the carbon fiber beam is extremely small, and unlike aluminum alloy beams, there is no frequent need for adjustment due to temperature changes or long-term operation. This not only extends the service life of the equipment, but also significantly reduces downtime due to maintenance, improving the overall efficiency of the production line.

Application prospects of carbon fiber beams in the dispensing machine industry

The introduction of carbon fiber beams not only improves the performance of the dispensing machine, but also brings significant cost reduction and efficiency improvement effects to the company. In the electronics field, carbon fiber beams ensure precise dispensing of tiny parts, improving product reliability and stability; in automotive manufacturing, it supports rapid dispensing of complex structures and improves the overall efficiency of the production line; in aerospace In the medical field, the high precision and stability of carbon fiber beams are indispensable to ensure the precise assembly of key components.

As carbon fiber technology continues to mature and costs are further reduced, carbon fiber beams are expected to be more widely used in the dispensing machine industry. It will become a new tool for reducing costs and increasing efficiency in the dispensing machine industry, and promote the development of the manufacturing industry towards a more efficient, more precise and more environmentally friendly direction. As a leader in carbon fiber technology, Hithunder will continue to be committed to the research and development and innovation of carbon fiber beams, bringing more surprises and breakthroughs to the dispensing machine industry.