At the recent Hannover LASERFAIR Shenzhen, Shenzhen Hithunder Carbon Fiber Technology Co., Ltd. demonstrated how its innovative carbon fiber technology can transform the laser processing industry. The expo, themed "Light Connects All, Igniting the Future", highlighted the critical role of technological breakthroughs in driving the laser industry forward.

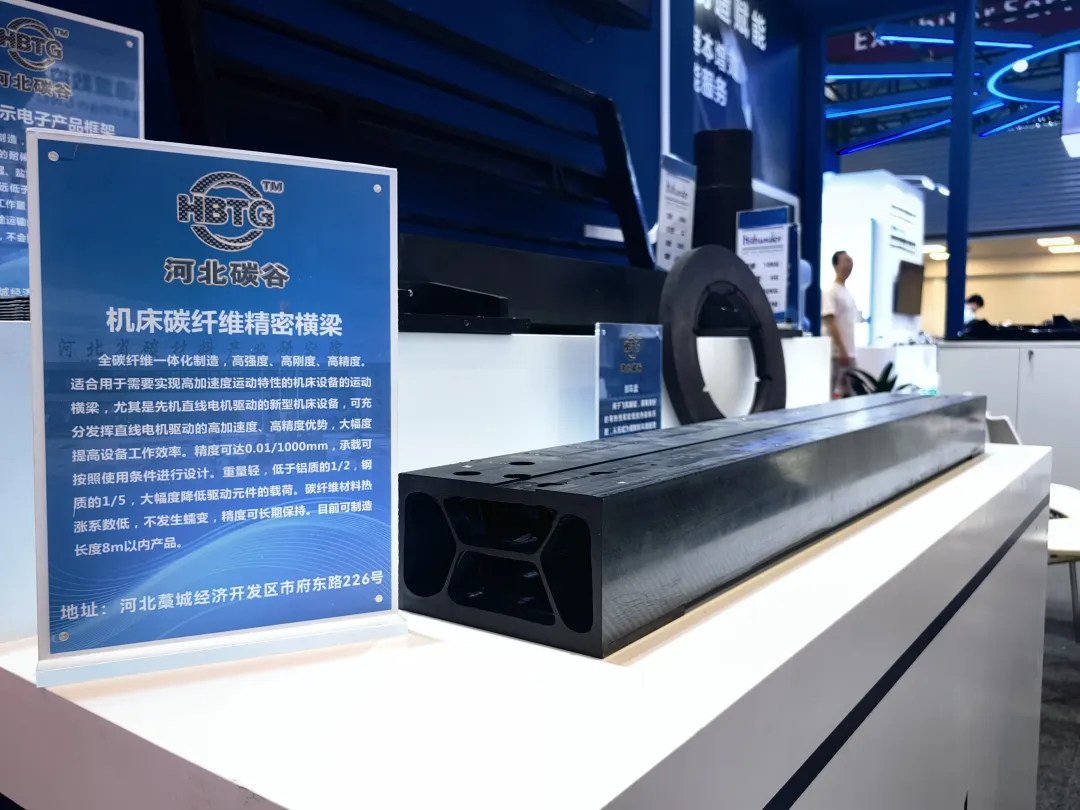

As laser cutting machines face intensifying market competition and a need for greater innovation, Hithunder's carbon fiber solutions emerged as a game-changing technology. The company's carbon fiber beams (also know as hollow multi-chamber carbon fiber tube), in particular, captivated attendees with their exceptional performance characteristics.

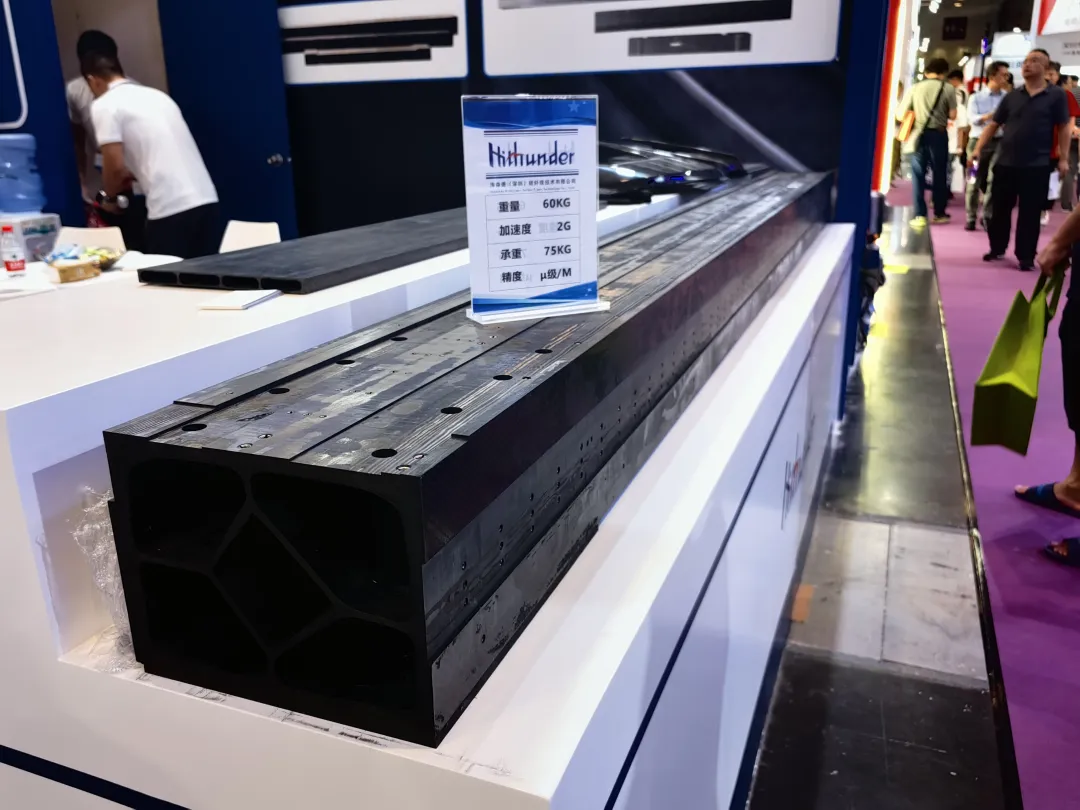

Hithunder's carbon fiber beams boast unparalleled strength, rigidity, and precision - essential attributes for high-speed, high-accuracy laser cutting applications. Weighing less than half of aluminum and a mere one-fifth of steel, these lightweight components significantly reduce the load on the machine's drive systems. This allows laser cutting machines to fully harness the speed and precision of linear motor technology, boosting productivity and efficiency to new heights.

"In comparative testing, our carbon fiber beams enabled laser cutting machines to achieve acceleration of up to 4G - a level that would be exorbitantly costly to reach with traditional steel or aluminum designs," explained the Hithunder technical team. "The combination of light weight and high stiffness is a true game-changer for the laser industry."

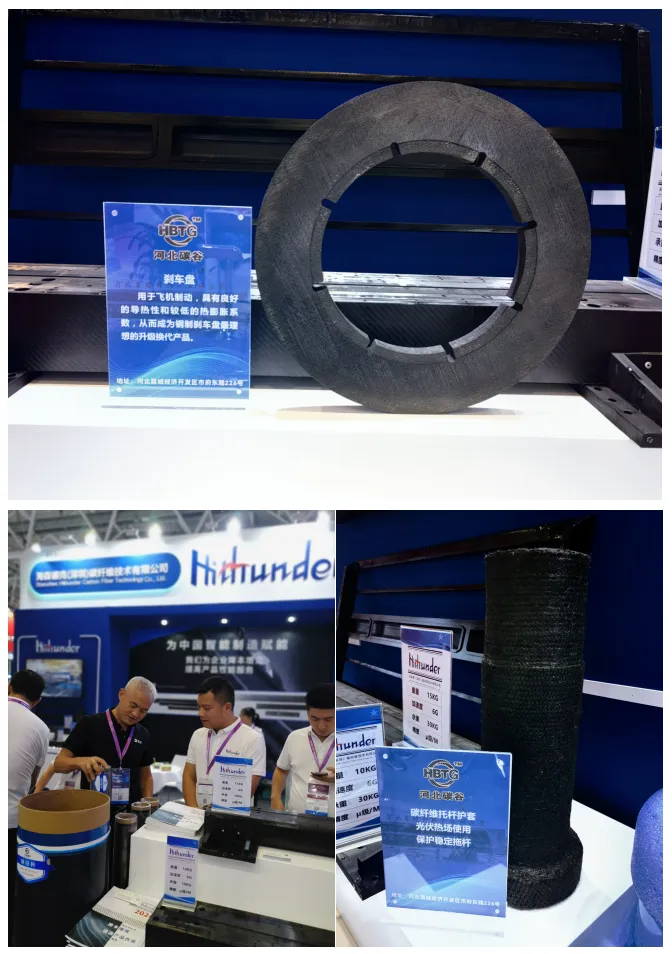

Beyond the beams, Hithunder showcased a range of other innovative carbon fiber products, including brake discs, support sleeves, and display brackets. These advanced materials not only enhance performance but also contribute to weight savings, prolonged service life, and reduced maintenance costs - crucial factors for laser equipment manufacturers and end-users alike.

Hithunder's carbon fiber solutions are designed with customization in mind, allowing the company to tailor products to the unique requirements of each customer's laser machines and applications. This level of flexibility ensures a perfect fit and optimal performance in diverse laser processing environments.

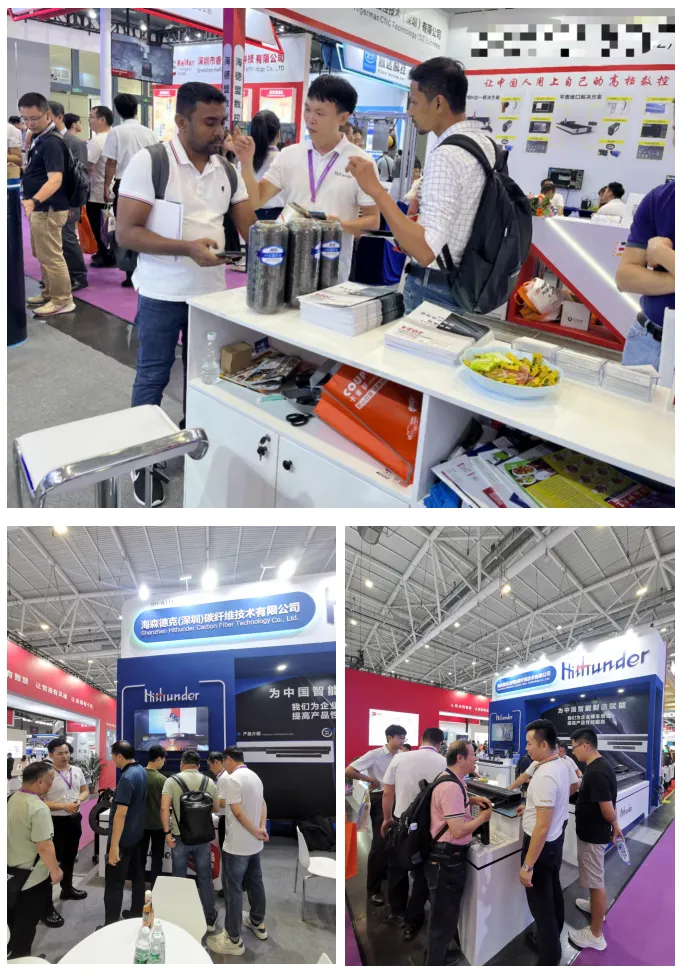

During the Shenzhen Laser Expo, visitors flocked to Hithunder's booth in Hall 9, Booth A111, eager to learn more about the company's cutting-edge technology and explore potential collaboration opportunities. The Hithunder team welcomed the chance to engage directly with international customers, sharing their expertise and vision for the future of laser processing.

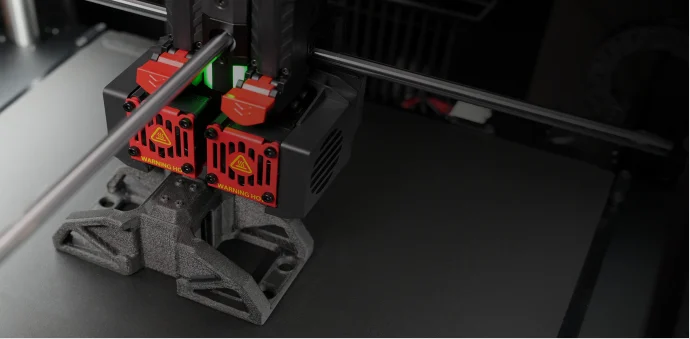

"We are excited to bring our carbon fiber innovations to the global laser industry, automobile industry, 3D printer industry, etc." said the Hithunder spokesperson Lee. "By working closely with our customers, we aim to unlock new levels of performance, efficiency, and cost-effectiveness - ultimately driving the entire laser processing sector forward."