In the quest for more efficient and sustainable energy production, the wind energy sector has increasingly turned to innovative materials that offer superior performance and durability. One of the most significant advancements in this area is the use of Carbon Fiber Wind Turbine Blades. By leveraging the unique properties of carbon fiber, manufacturers are designing blades that are not only stronger and lighter but also more cost-effective in the long run.

The Power of Carbon Fiber in Wind Turbine Blade Design

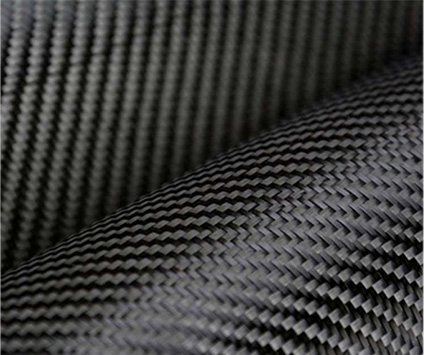

Carbon fiber is a high-performance material known for its exceptional strength-to-weight ratio. This makes it an ideal choice for applications that require both durability and reduced weight, which is critical for the performance of wind turbine blades. With wind turbines growing in size and the demand for efficiency increasing, carbon fiber's ability to withstand extreme weather conditions while being lightweight is revolutionizing the industry.

Benefits of Carbon Fiber Wind Turbine Blades

Enhanced Strength and Durability

The primary advantage of Carbon Fiber Wind Turbine Blades lies in their unmatched strength. The carbon fiber's inherent properties allow the blades to endure the immense mechanical stress generated by the wind, reducing wear and tear. This longevity translates into fewer repairs and replacements, ultimately saving operational costs for wind energy providers.Reduced Weight for Greater Efficiency

Traditional materials such as fiberglass or steel, while strong, often add significant weight to the turbine blades. The reduced weight of carbon fiber blades leads to improved aerodynamics, enabling the blades to spin more efficiently with less wind force required. This makes the turbines more effective, particularly in low-wind areas, and helps generate more energy.Improved Fatigue Resistance

Wind turbines are subjected to constant cyclic loading, which can lead to material fatigue over time. Carbon Fiber Wind Turbine Blades are exceptionally resistant to fatigue, meaning they maintain their structural integrity for longer periods. This enhanced resistance ensures a longer lifespan for the blades and optimizes the performance of the wind turbine over its operational life.Corrosion Resistance

Carbon fiber's resistance to corrosion is another key advantage. Unlike metals and some composites, carbon fiber does not degrade when exposed to moisture, salt, or other corrosive agents. This is particularly important for turbines located in coastal or offshore environments, where the blades are exposed to harsh conditions.

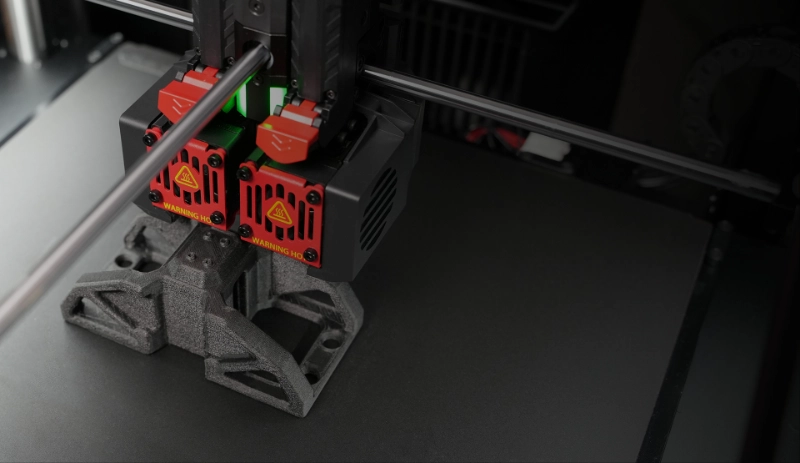

The Role of Hithunder Carbon Fiber Technology in Advancing Wind Energy

At Hithunder Carbon Fiber Technology, we specialize in the research, development, production, and sales of carbon fiber products, including carbon fiber wind turbine blades. Our commitment to providing high-quality materials has driven us to innovate and improve the manufacturing process for carbon fiber-based components. We understand the critical role that carbon fiber plays in enhancing the efficiency and sustainability of wind energy, and we are proud to be part of this technological advancement.

Our high-performance carbon fiber wind turbine blades are designed with cutting-edge technology that ensures they meet the stringent demands of the wind energy sector. Whether it's through advanced manufacturing techniques or continuous material enhancements, we strive to deliver blades that not only improve energy output but also contribute to a greener, more sustainable future.

The Future of Wind Turbine Technology

As the demand for renewable energy grows, the importance of carbon fiber wind turbine blades cannot be overstated. The combination of strength, lightweight properties, and durability makes carbon fiber an essential material for next-generation wind turbines. The ongoing innovations in material science and manufacturing processes will continue to push the boundaries of what’s possible in the wind energy sector, making wind power more reliable, cost-effective, and sustainable.

In the near future, carbon fiber wind turbine blades will likely become the industry standard, replacing traditional materials in favor of more efficient, longer-lasting options. As a leading carbon fiber manufacturer, Hithunder Carbon Fiber Technology is dedicated to supporting this transformation by providing top-quality carbon fiber products tailored to meet the needs of the evolving renewable energy market.

Conclusion

The use of carbon fiber in the design of wind turbine blades has opened up new possibilities for the wind energy industry. By providing stronger, lighter, and more durable blades, carbon fiber technology is enhancing the overall performance of wind turbines. With companies like Hithunder Carbon Fiber Technology leading the charge, the future of wind energy is brighter than ever. As we continue to develop and refine carbon fiber materials, the impact on global energy production will be profound, helping to create a more sustainable and environmentally-friendly world.

Hithunder Carbon Fiber Technology is here to provide the carbon fiber wind turbine blades that will power the future. Let's work together to harness the power of wind in the most efficient way possible.