On July 9th, a technology showcase focusing on intelligent machine tools and industrial services was held under the theme "Towards New Breakthroughs, Leading the Future". Dongfeng Machine Tool Plant hosted the new product launch event, drawing nearly a hundred guests from government, various industries, and partner organizations. They gathered to discuss the new blueprint for intelligent equipment development and witness this milestone moment.

At the event, Dongfeng Machine Tool Plant unveiled its "4+1+1" new product line-up, concentrating on two core business areas: machine tools and industrial services. It covers five key domains - integrated die-casting, lightweight and efficient processing, new energy drivetrain, flexible FMS, and smart operation & maintenance. This provides comprehensive solutions for processing components like new energy motors, battery housings, steering knuckles, as well as super-large integrated die-cast parts and lightweight aluminum alloy parts. It also enables flexible production lines and full life-cycle industrial maintenance.

4 New Machine Tool Products:

1. DDG160 Dual Crossbeam High-Speed Gantry Machining Center

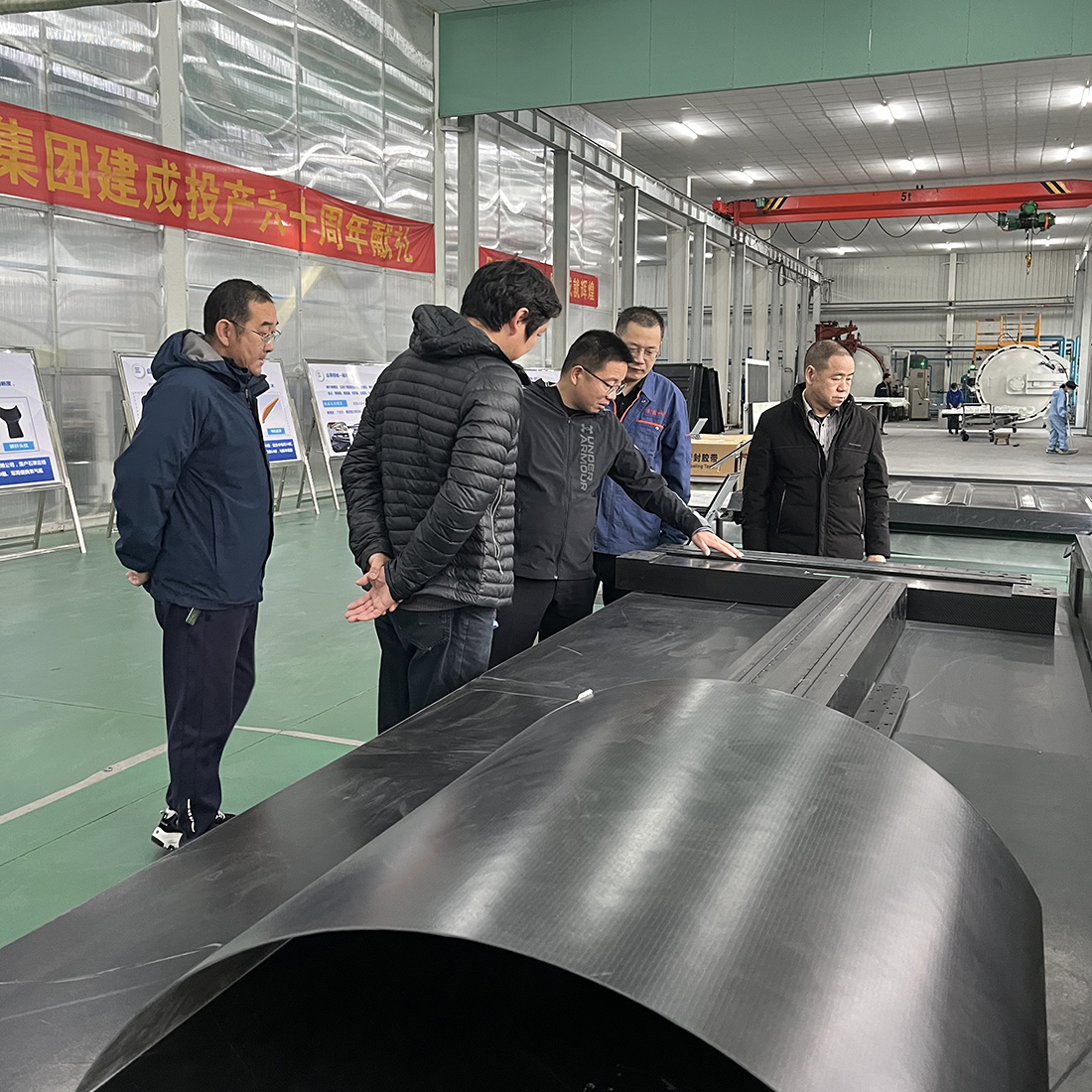

Designed for large integrated components in new energy vehicles, it features high speed, long stroke and lightweight construction. It delivers a CNC machine tool solution with integrated process, logistics, inspection and maintenance capabilities. Through collaboration with Hithunder Group, this model will adopt carbon fiber beams to boost acceleration from 0.7g to 1.5g, significantly improving accuracy, efficiency and stability, while reducing after-sales costs. The machine is well-suited for precision machining, milling, gun drilling and interchangeable components of critical powertrain parts, achieving world-class precision.

2. DQ800 Long-Stroke High-Speed Horizontal Machining Center

Tailored for processing new energy vehicle sub-frames and multi-function motor housings, with self-developed core components like tool magazine and rotary table.

3. DDL500 Dual-Spindle Vertical Machining Center & DDZ40 Dual-Spindle Horizontal Machining Center

Designed for machining new energy vehicle motor housings, battery housings and steering knuckle components. The dual-spindle design reduces footprint by 40%, costs by 30% and energy consumption by 25%, while maintaining high precision across the full stroke.

Standing on a new foundation, Dongfeng Machine Tool Plant is setting fresh goals, exploring innovative technologies, and applying advanced carbon fiber composites with Hithunder Group to push the performance boundaries of its equipment. This will contribute tremendous impetus to the industry's development and provide even more sophisticated solutions.