Drones have rapidly evolved from niche hobbyist gadgets to essential tools used across various industries, from agriculture and photography to logistics and military applications. As the demand for drones grows, so does the need for improved performance, efficiency, and durability. One of the key materials driving these advancements is carbon fiber—a lightweight yet incredibly strong material that plays a crucial role in enhancing the durability and performance of drones.

In this article, we'll explore how carbon fiber contributes to making drones more robust, efficient, and capable of handling more demanding tasks. We’ll also highlight the work of Hithunder Composite Materials Technology, a leading high-tech company specializing in the research, development, and production of composite materials, including carbon fiber components, and their role in advancing drone technology.

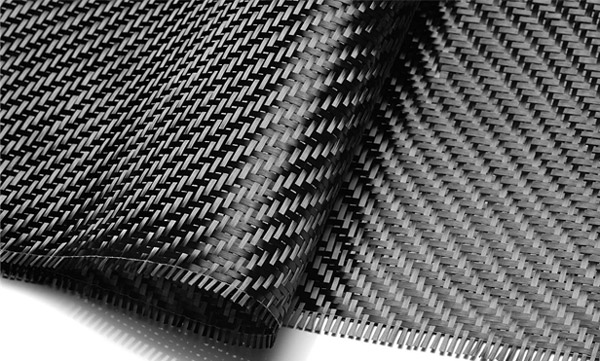

What is Carbon Fiber?

Carbon fiber is a synthetic polymer made from carbon atoms bonded together to form long, thin strands that are woven into a fabric. It is renowned for its high strength-to-weight ratio, meaning that carbon fiber is incredibly strong while remaining much lighter than materials like steel or aluminum. This unique combination of lightness and strength makes carbon fiber an ideal material for drone components that need to be both durable and efficient in flight.

The Role of Carbon Fiber in Drone Durability

1. Increased Strength and Resistance to Impact

Drones, especially those used for commercial or military purposes, are often exposed to harsh conditions, whether it’s high-speed flight, rugged terrain, or unexpected crashes. Carbon fiber’s exceptional strength provides a high degree of durability, allowing drones to withstand impacts and stresses that would typically damage components made from traditional materials like plastic or metal.

The toughness of carbon fiber ensures that drones are less prone to breaking or cracking upon impact. This is especially crucial for drones in military or industrial settings, where the cost of damage or failure can be significant. In these applications, having a drone frame made from carbon fiber can prevent costly repairs and downtime.

2. Improved Aerodynamics

The lightweight nature of carbon fiber contributes to improved aerodynamics. Drones with carbon fiber components are not only lighter but also benefit from better maneuverability, which is essential for flying in tight spaces or at high speeds. The reduced weight improves lift and minimizes drag, making it easier for drones to remain stable in the air while requiring less power for operation.

For example, when the arms, frame, and other major components of a drone are constructed from carbon fiber, the overall weight of the drone is reduced, allowing it to carry heavier payloads, fly for longer durations, and achieve faster speeds—all while maintaining excellent stability and control.

3. Corrosion Resistance

Unlike metals that are susceptible to rust and corrosion when exposed to moisture, carbon fiber is impervious to environmental factors such as humidity and water. This makes carbon fiber an ideal choice for drones that operate in diverse and challenging conditions, such as coastal or marine environments. Corrosion resistance ensures the longevity of drones, reducing the frequency of maintenance and replacement of parts due to environmental damage.

For industries that require drones to fly in varied climates—such as agriculture, military, or rescue operations—carbon fiber provides a dependable solution that allows for consistent performance without the risk of deterioration over time.

Enhancing Drone Performance with Carbon Fiber

1. Longer Flight Times

Because carbon fiber is lighter than many other materials, drones built with this material can fly longer on a single battery charge. The reduction in weight directly impacts the drone’s battery consumption, as lighter drones require less energy to stay aloft. This is particularly valuable for commercial applications where drones are tasked with long-duration flights, such as surveillance, mapping, or inspections.

With longer battery life, drones can stay in the air for extended periods, improving operational efficiency and productivity. This advantage is crucial in industries like logistics, agriculture, or energy where drones are often deployed for hours at a time.

2. Better Payload Capacity

Drones designed with carbon fiber components have a higher payload capacity compared to their counterparts made from heavier materials. The weight savings from carbon fiber allow drones to carry additional equipment such as cameras, sensors, or delivery packages without compromising flight performance.

This is particularly important in sectors such as surveying, cinematography, or cargo delivery, where drones are expected to carry advanced payloads while maintaining agility and precision. The ability to carry heavier loads without sacrificing performance opens up new possibilities for drone applications across various industries.

3. Reduced Wear and Tear

Drones are often subjected to repetitive stress and wear due to vibrations, frequent landings, and high-speed maneuvers. Carbon fiber’s durability and resistance to fatigue help minimize the effects of wear and tear on drone frames and components. This extends the lifespan of the drone, reducing the need for frequent repairs or replacements, which ultimately lowers operational costs for businesses using drones in high-volume or continuous-use environments.

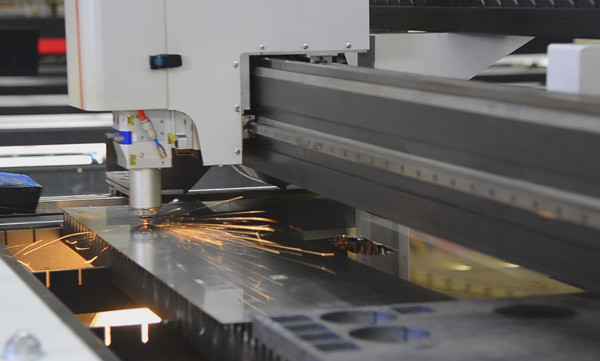

How Hithunder Composite Materials Technology Contributes to Drone Innovation

Hithunder Composite Materials Technology is at the forefront of integrating advanced composite materials, including carbon fiber, into industries that require high-performance products. As a leading company in the development and production of composite structural components, Hithunder’s technology plays a key role in advancing drone design and functionality.

With a focus on both aerospace and civilian applications, Hithunder brings cutting-edge carbon fiber solutions to the drone market, ensuring that manufacturers have access to top-quality materials for building more efficient and durable drones. Their dedication to innovation and market-driven design has led to the development of composite materials that offer a superior strength-to-weight ratio, corrosion resistance, and long-lasting performance—all essential features for modern drones.

By applying aerospace-grade composite materials to drone structures, Hithunder is helping to bridge the gap between military and civilian drone technology, allowing for the creation of drones that can withstand challenging environments, operate at peak performance, and provide value across various sectors.

Conclusion

Carbon fiber is undeniably one of the most transformative materials in the drone industry, offering significant improvements in durability, performance, and efficiency. Its lightweight, strength, and corrosion-resistant properties make it the material of choice for manufacturers aiming to build drones capable of handling demanding tasks and tough conditions.

For those seeking to develop or purchase high-quality drones, working with trusted suppliers like Hithunder Composite Materials Technology ensures that you’re using cutting-edge carbon fiber and composite solutions that maximize the potential of your drone fleet. Whether you're operating drones for commercial, military, or recreational purposes, carbon fiber will continue to play a critical role in enhancing both the durability and performance of next-generation drones.