The drone industry has seen rapid growth in recent years, with an ever-expanding range of applications in sectors like agriculture, surveillance, logistics, and more. As drones become an integral part of industries across the globe, the demand for more efficient, durable, and lightweight drones continues to rise. This is where carbon fiber drones come into play, marking a significant evolution in aerial technology. Companies like Hithunder Composite Materials Technology, a high-tech leader specializing in advanced composite materials for aerospace and defense applications, are pioneering this shift, helping to push the boundaries of drone technology.

The Advantages of Carbon Fiber in Drone Construction

Carbon fiber has emerged as the material of choice for the next generation of drones. Here's why:

Lightweight Strength: Carbon fiber is renowned for its high strength-to-weight ratio. When applied to drone frames, this material significantly reduces the overall weight without compromising the durability and structural integrity of the drone. This leads to improved flight times, better payload capacity, and enhanced maneuverability, making carbon fiber drones ideal for commercial and industrial use.

Enhanced Durability: Drones are subject to harsh environments, whether they’re operating in extreme temperatures, high winds, or heavy rain. Carbon fiber is highly resistant to corrosion, fatigue, and impact damage. This makes drones constructed with carbon fiber less prone to wear and tear, resulting in longer lifespans and reduced maintenance costs for operators.

Improved Performance: Because of the material’s stiffness, carbon fiber helps maintain a drone’s structural integrity under stress, ensuring smoother and more stable flight, even in turbulent conditions. The improved aerodynamic properties of carbon fiber also contribute to increased flight efficiency, reduced energy consumption, and more precise control during flight.

Design Flexibility: Carbon fiber allows for greater design flexibility in drone construction. It can be molded into complex shapes that provide optimal aerodynamics and performance. This flexibility opens up possibilities for new types of drone designs, from smaller, more compact drones to larger, more powerful models used for heavy-lift or long-range operations.

The Role of Hithunder Composite Materials Technology in the Evolution of Carbon Fiber Drones

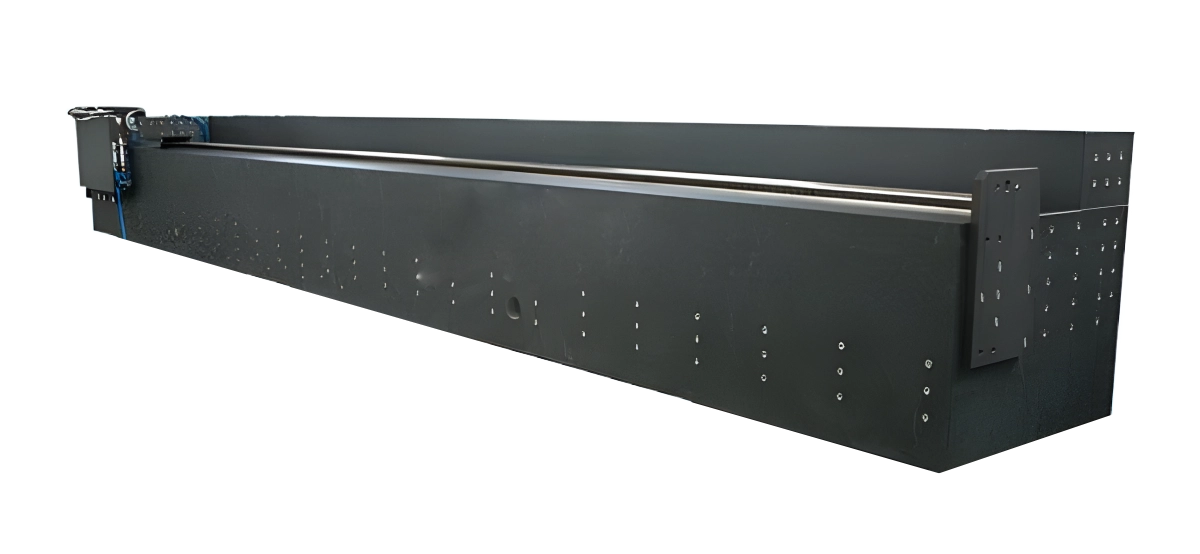

At the forefront of integrating advanced composite materials into drone technology is Hithunder Composite Materials Technology, a high-tech company dedicated to researching and producing composite structural components for the aerospace and defense industries. With a commitment to technological innovation and market-driven approaches, Hithunder has been instrumental in transferring aerospace-grade composite technologies into the civilian drone industry.

Hithunder’s expertise lies in developing cutting-edge materials that combine the strength of carbon fiber with the versatility required for a wide range of drone applications. By bringing aerospace innovation into the commercial sector, the company is enabling the next generation of drones to achieve performance levels that were once reserved for military or high-end industrial equipment.

The Future of Drone Technology

The future of drones is undoubtedly tied to the development of lighter, stronger, and more efficient materials, and carbon fiber will continue to be at the heart of this transformation. As more companies like Hithunder push the boundaries of composite materials in aerospace technology, we can expect drones to become even more advanced, with enhanced capabilities for industries ranging from logistics and delivery to search and rescue and environmental monitoring.

Furthermore, the use of carbon fiber in drones is paving the way for more sustainable aerial technologies. Carbon fiber's efficiency in reducing weight and energy consumption translates into longer flight times and reduced carbon footprints, which is crucial as industries look to move toward greener technologies. The integration of carbon fiber into drone construction can also facilitate the development of drones that are capable of operating over longer distances and in more challenging environments, which could lead to more widespread use in remote areas or for disaster relief operations.

Conclusion

As we look toward the future of aerial technology, carbon fiber drones are poised to lead the way. Thanks to advancements from companies like Hithunder Composite Materials Technology, the dream of lightweight, durable, and high-performing drones is becoming a reality. With the continued evolution of materials science, drones will soon be capable of even more impressive feats, offering transformative benefits for industries around the world and opening the door to new possibilities in aviation technology. Carbon fiber is not just the future of drones—it’s the future of aerial technology itself.