In recent years, the use of carbon fiber beams has revolutionized the aerospace and automotive industries, offering a perfect combination of strength, durability, and light weight. As these industries continue to push the boundaries of performance, safety, and fuel efficiency, carbon fiber beams have emerged as a vital material. Their exceptional properties make them indispensable for the development of high-performance products, especially in environments where every ounce matters.

In this blog, we’ll explore the many benefits and applications of carbon fiber beams, highlighting how companies like Hithunder Composite Materials Technology, a high-tech company specializing in the development and production of composite materials, are driving innovation in these industries.

What Are Carbon Fiber Beams?

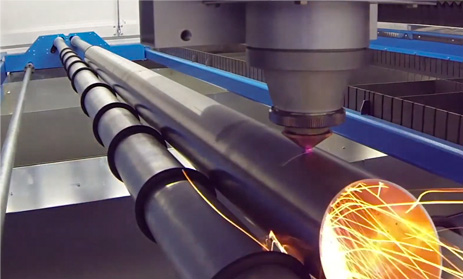

Carbon fiber beams are structural components made from carbon fibers that are woven into a fabric and then impregnated with resin to form a solid, rigid beam. These beams combine the high strength of carbon fiber with the flexibility needed for various applications, resulting in components that are both lightweight and incredibly strong. Their versatile properties allow them to be used in a wide range of industries, but the aerospace and automotive sectors are particularly dependent on them due to their unique needs.

Key Benefits of Carbon Fiber Beams

1. Strength and Light Weight

One of the most appealing features of carbon fiber beams is their exceptional strength-to-weight ratio. Carbon fiber is one of the strongest materials available, yet it is significantly lighter than metals like steel and aluminum. This makes carbon fiber beams perfect for aerospace and automotive applications, where reducing weight without sacrificing strength is crucial.

In aerospace, lighter components mean improved fuel efficiency and the ability to carry more cargo or passengers. Similarly, in automotive design, reducing the weight of vehicles can enhance performance, fuel efficiency, and overall driving dynamics.

2. Corrosion Resistance

Unlike metals, carbon fiber beams are highly resistant to corrosion. In both aerospace and automotive industries, components are often exposed to harsh environmental conditions such as moisture, salt, and chemicals. The corrosion-resistant nature of carbon fiber ensures that these beams will retain their strength and performance, even when exposed to these elements. This makes carbon fiber an ideal choice for long-term, low-maintenance solutions in these industries.

3. Improved Performance

By using carbon fiber beams, both the aerospace and automotive industries can significantly improve the performance of their products. In aerospace, the reduction in weight leads to better fuel efficiency, while in the automotive sector, lighter vehicles offer improved handling, faster acceleration, and better overall driving performance.

Additionally, carbon fiber’s ability to absorb vibrations and reduce noise makes it a preferred material for enhancing the comfort and stability of aircraft and vehicles alike.

4. High Durability and Longevity

Carbon fiber beams are highly durable and resistant to wear and fatigue. Unlike other materials, carbon fiber does not degrade under stress and retains its integrity for a much longer period. In the aerospace industry, where components need to withstand high levels of stress and extreme temperatures, carbon fiber beams offer a longer lifespan with less maintenance compared to traditional materials.

This durability also translates to the automotive industry, where carbon fiber beams enhance the longevity of vehicles, requiring fewer repairs and replacements over time.

5. Design Flexibility

Carbon fiber beams are incredibly versatile in terms of design. Thanks to their malleability, carbon fiber can be molded into complex shapes to meet the specific needs of different projects. Whether it’s an intricate aerospace component or a lightweight, high-strength automotive beam, carbon fiber offers design flexibility that traditional materials cannot match. This opens up numerous possibilities for engineers and designers to create customized, high-performance components.

Applications of Carbon Fiber Beams in Aerospace and Automotive Industries

1. Aerospace Industry

In aerospace, carbon fiber beams are used in critical structural components due to their lightweight yet robust properties. Some key applications include:

Aircraft Fuselages and Wings: Carbon fiber beams are increasingly used in the wings, fuselages, and tail sections of aircraft. These beams reduce the overall weight of the aircraft, which in turn improves fuel efficiency and reduces operational costs. Lightweight, high-strength carbon fiber beams contribute to the aircraft’s overall structural integrity and performance.

Engine Components: Carbon fiber beams are used in components such as engine brackets and supports, where high strength and heat resistance are critical. They are capable of withstanding the extreme conditions in an aircraft engine without adding unnecessary weight.

Interior Structures: Carbon fiber beams are also used in the construction of interior frames and support structures within the aircraft, where reducing weight while maintaining strength is crucial for both safety and comfort.

2. Automotive Industry

In the automotive industry, carbon fiber beams are widely used for performance and safety improvements. Some applications include:

Chassis and Body Frames: Carbon fiber beams are incorporated into chassis and body frames of high-performance vehicles. These beams provide strength and durability without adding weight, contributing to better handling, speed, and fuel efficiency.

Suspension Systems: In high-performance vehicles and sports cars, carbon fiber beams are used in suspension systems to reduce weight while maintaining the rigidity and strength needed for optimal performance. The ability of carbon fiber to handle high-stress conditions makes it a great fit for components like control arms, strut bars, and shock mounts.

Electric Vehicles (EVs): With the rise of electric vehicles, manufacturers are increasingly turning to carbon fiber beams to reduce vehicle weight and increase range. Carbon fiber components help maximize battery efficiency by reducing the overall weight of the vehicle.

Interior Components: Carbon fiber is also used in the interior of luxury and sports cars, where aesthetic appeal and performance are both important. Carbon fiber beams can be found in dashboards, door beams, and center consoles, where their lightweight nature enhances vehicle performance.

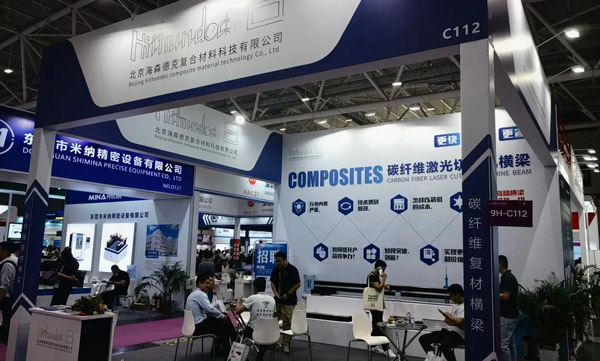

How Hithunder Composite Materials Technology Leads Innovation

Hithunder Composite Materials Technology is at the cutting edge of developing and producing carbon fiber solutions for the aerospace and automotive industries. As a company specializing in composite material structural components, Hithunder is committed to advancing the capabilities of carbon fiber beams, ensuring that each product meets the stringent requirements of these high-performance sectors.

With a focus on research, development, and production, Hithunder provides customized composite solutions for aerospace and automotive manufacturers, offering tailored carbon fiber beams designed to enhance performance, reduce weight, and improve overall durability. Their expertise in composite materials ensures that Hithunder's products remain at the forefront of technology, helping their clients stay ahead in an ever-evolving market.

Conclusion

Carbon fiber beams are transforming both the aerospace and automotive industries by offering a material that is simultaneously lightweight, strong, durable, and versatile. These beams provide the ideal solution for companies looking to improve the performance, fuel efficiency, and safety of their products. As industries continue to seek more efficient and effective materials, carbon fiber will remain a key player in shaping the future of aerospace and automotive engineering.

With the expertise of companies like Hithunder Composite Materials Technology, businesses in these industries can access high-quality, cutting-edge solutions that meet their unique needs, pushing the boundaries of what’s possible in modern engineering. As technology continues to evolve, the role of carbon fiber beams in the design and manufacturing of high-performance products will only grow more significant.